808nm 100mW Semiconductor Laser Coupled PM Optical Fiber

808nm fiber-coupled laser uses PM fiber coupling, which has the advantages of high coupling efficiency and good output laser beam quality. The TEC temperature control system is used to ensure that the laser is more stable and has better performance. Compact structure, strong and reliable, suitable for various industrial and scientific research applications.

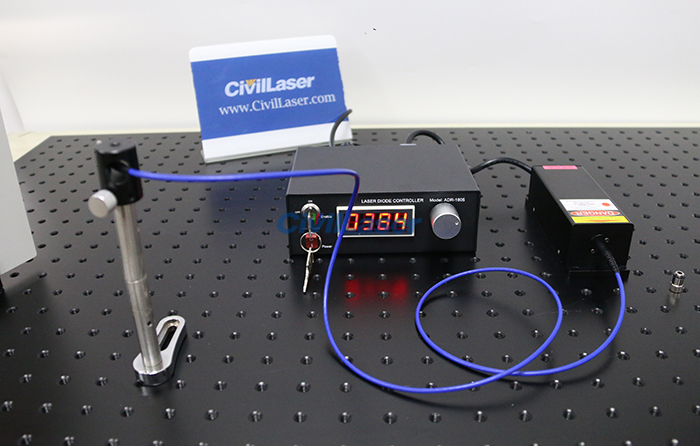

This is 808nm 100mW infrared lab laser system coupled PM fiber. The working voltage is AC 90~240V and supports wide range voltage. Its laser power can be adjusted from 0~100mW, and it supports two working modes of CW/Modulation.

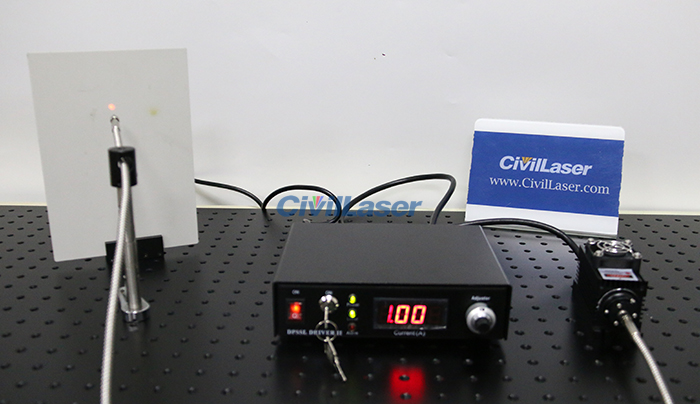

808nm is infrared laser, invisible laser, here use infrared sensitive film to observe the spot.

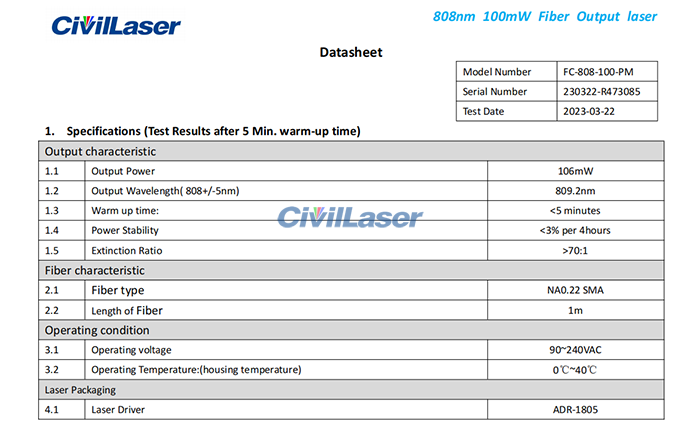

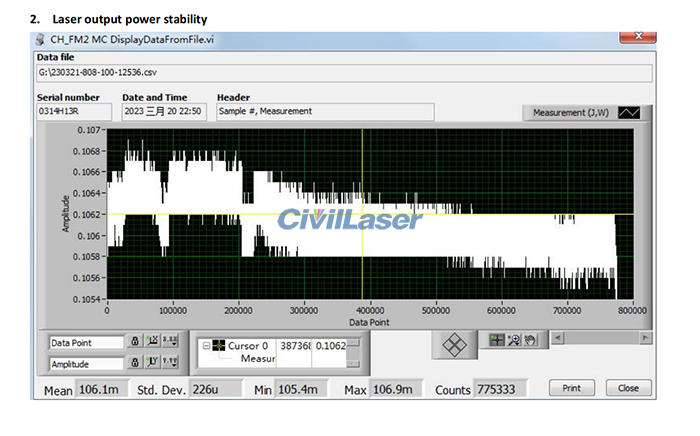

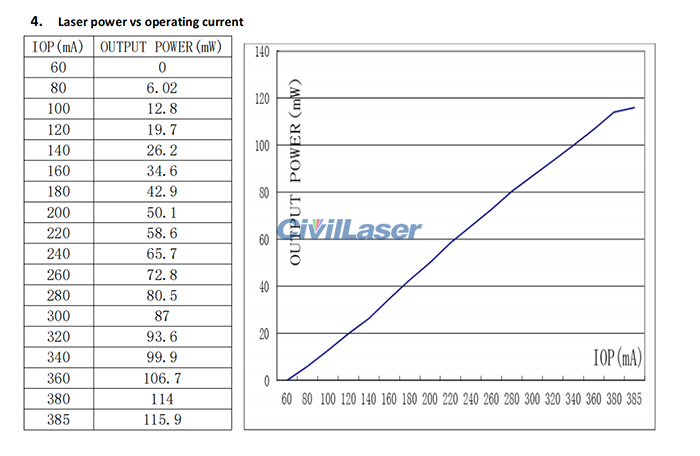

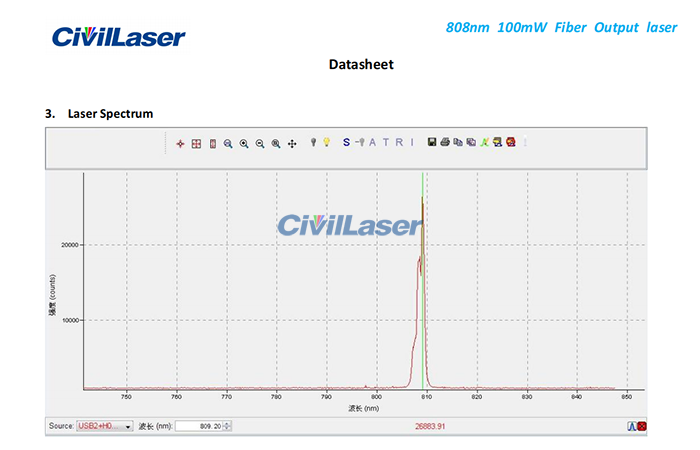

The test report of 808nm 100mW IR PM fiber coupled laser system.

37dBm Yb-doped SM Fiber Amplifier Benchtop

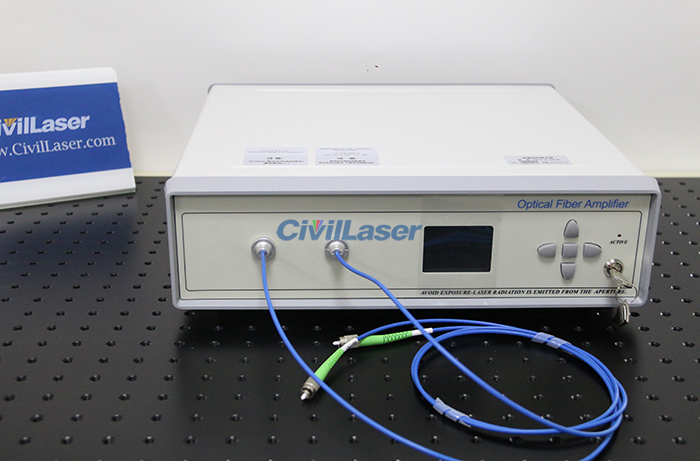

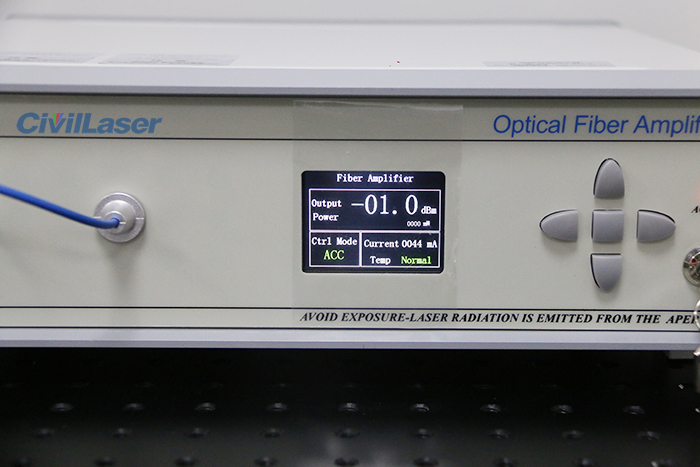

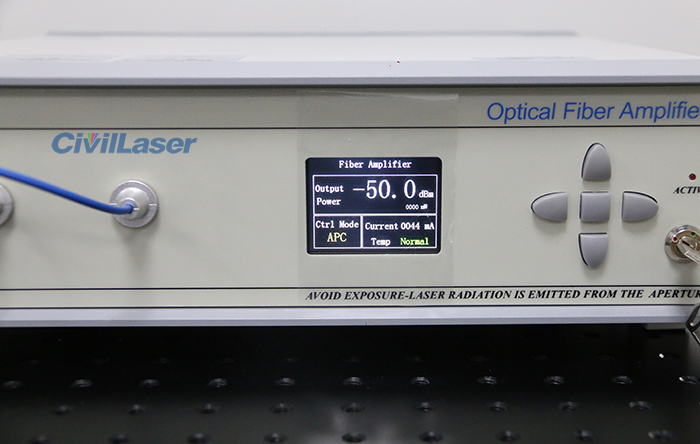

It’s a high power Ytterbium-doped optical amplifier, its output power is 37dBm. And high power YDFA built-in 3 cooling fans. The software control function can be customized, and the default is button control. The current working mode, current and output power are displayed on the front display.

It supports APC and ACC two working modes, and the two modes can be switched. In ACC mode, the working current can be adjusted. In APC mode, the output power can be adjusted.

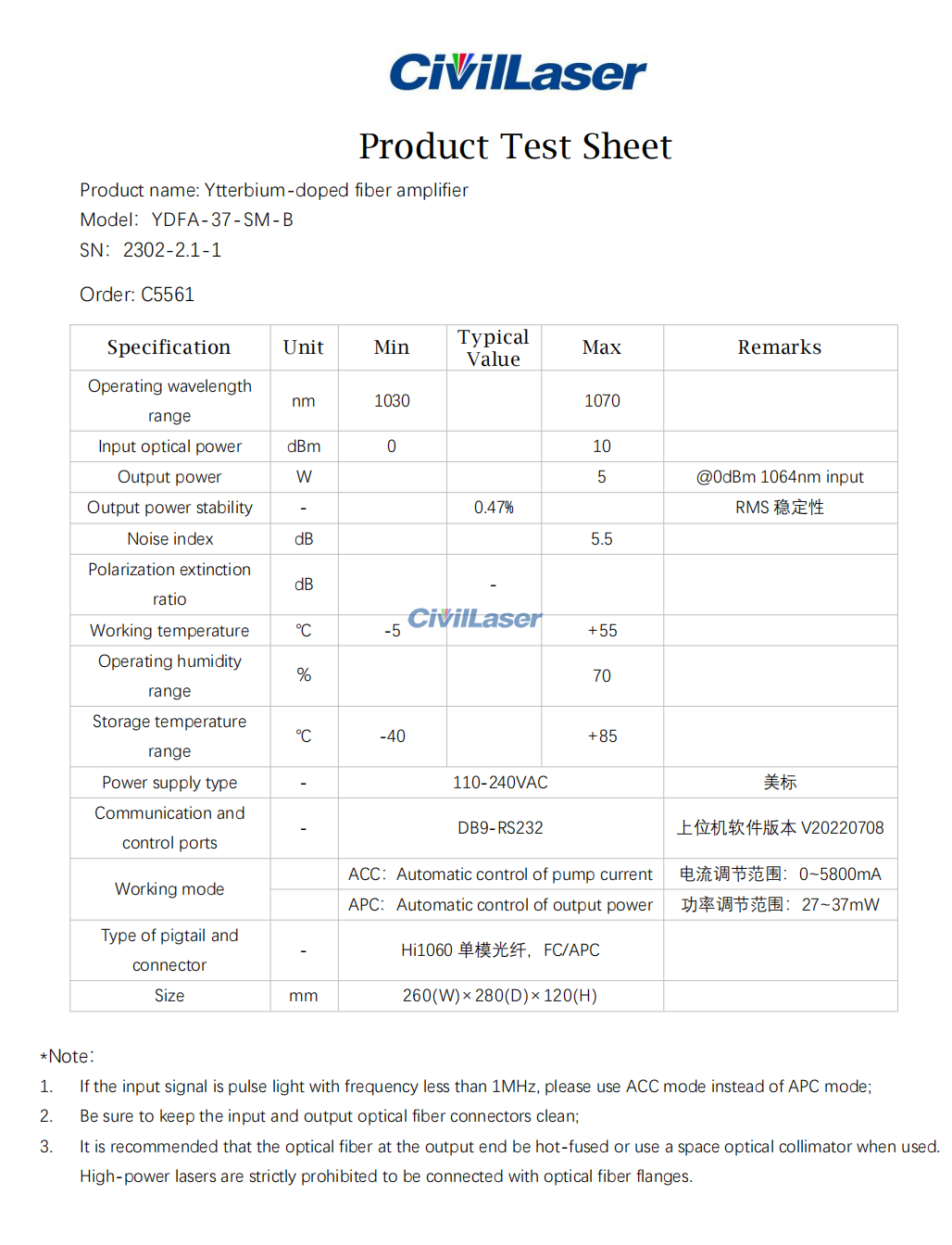

The test report of YDFA-37-SM.

1030~1100nm 10W PM Optical Fiber Amplifier YDFA

Ytterbium-doped fiber amplifier (YDFA) generates gain by pumping ytterbium-doped fiber with a semiconductor laser, and is used to amplify laser signals in the 1030~1100nm band. PM980 polarization-maintaining fiber output, the output power is continuously adjustable, and has the advantages of high gain and low noise. The desktop YDFA is convenient for experimental operation, and the user can adjust the pump current and output power through the buttons on the front panel. A more compact modular YDFA is also available, which is convenient for users’ system integration. Both desktop YDFA and modular YDFA can support PC software control and serial port command control.

The following video explains the 40dBm polarization maintaining YDFA becnhtop. It supports APC and ACC two working modes can be switched. In APC mode, the output power can be adjusted. In ACC mode, the working current can be adjusted. Let’s check it now.

It’s a high power polarization maintaining ytterbium-doped optical amplifier. Civil Laser’s 10W high power YDFA include a ‘Monitor’ fiber. The software control function can be customized, and the default is button control. The working current or output power can be adjusted by the button.

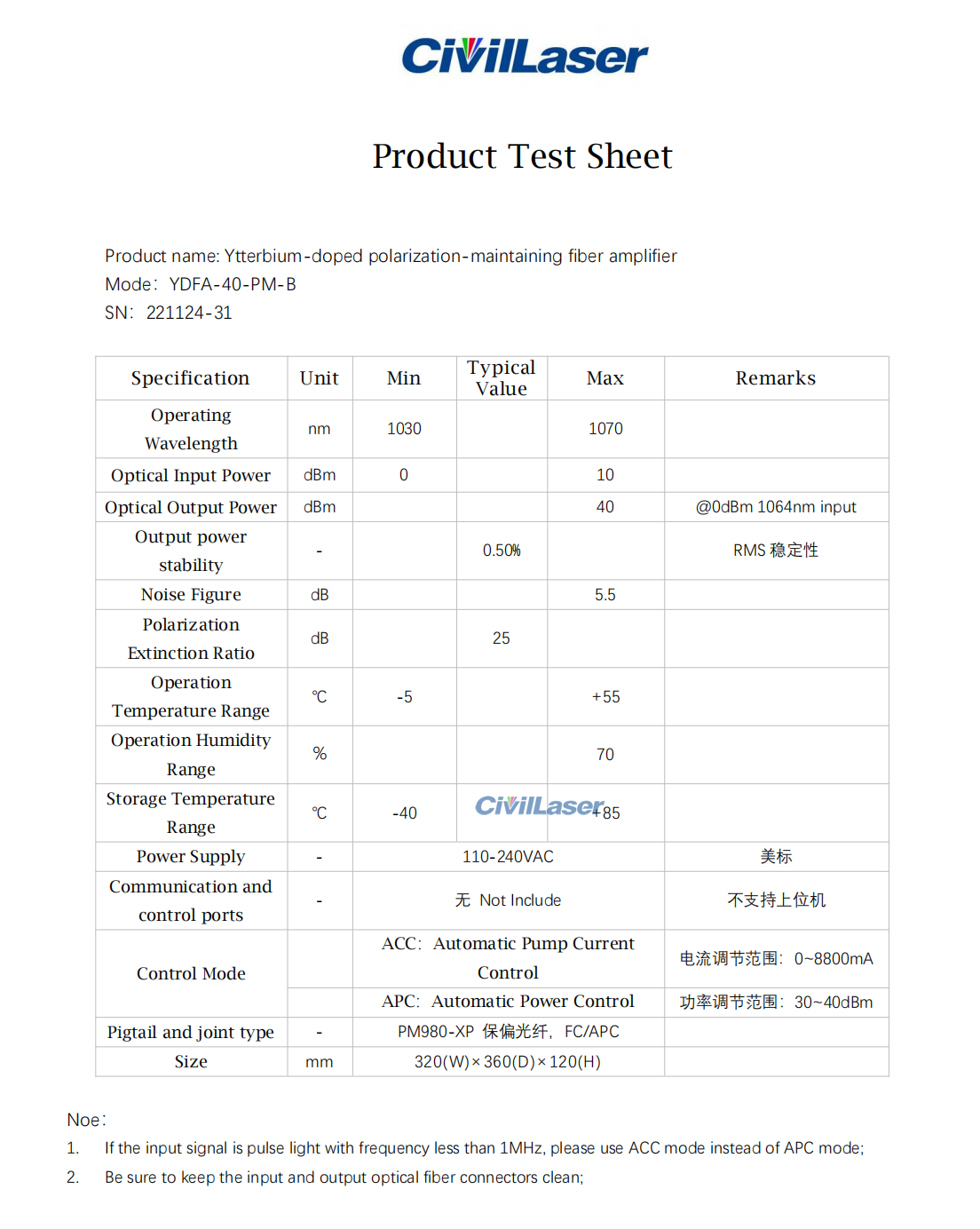

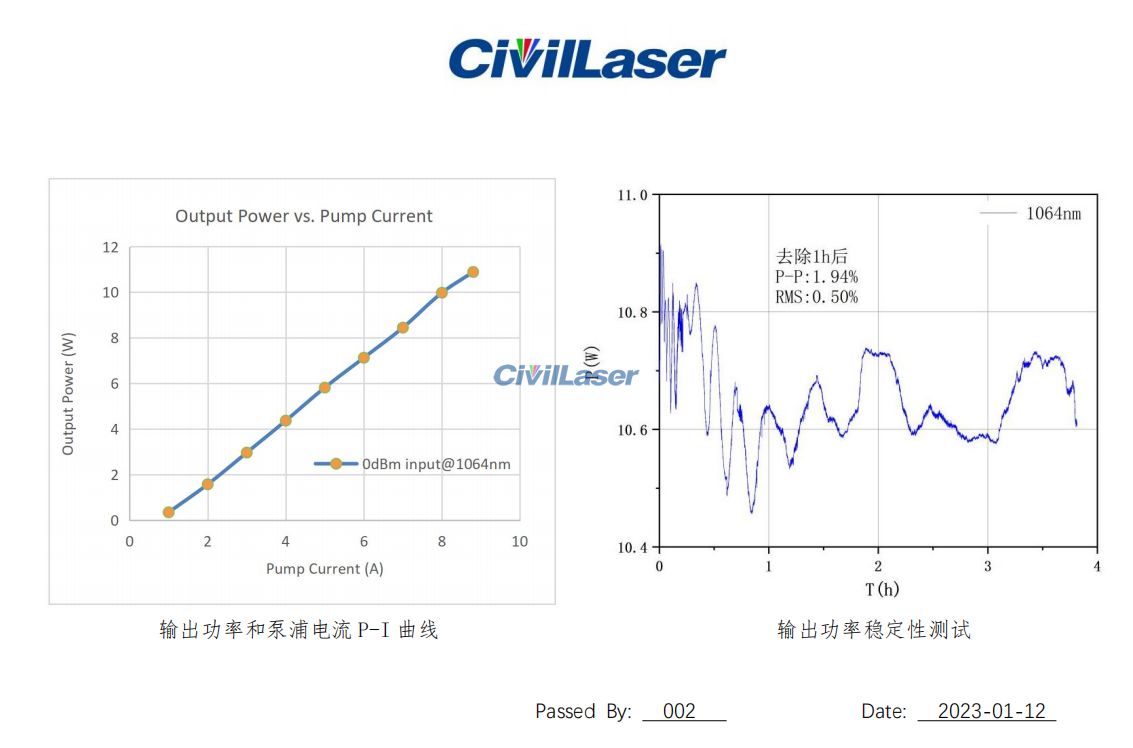

YDFA’s test report.

520nm 22W Lab Laser Fiber Output PC Control

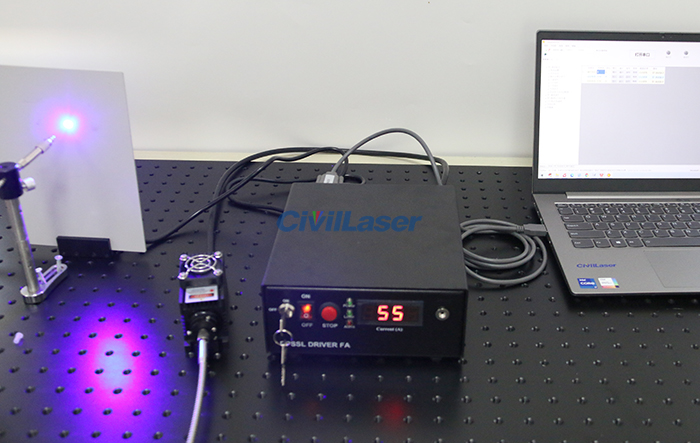

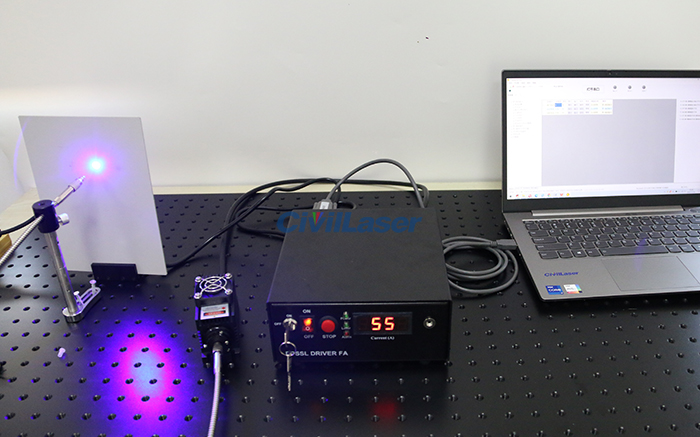

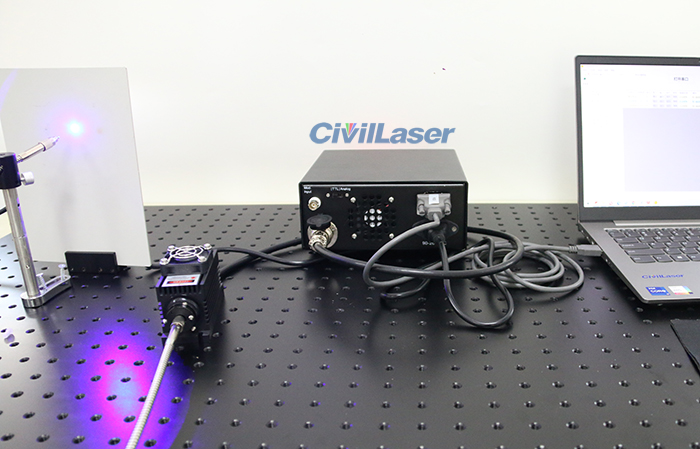

This is 520nm high power green fiber laser system. This laser adds software control. Use RS232-USB to connect the laser and computer software.The laser output power can be adjusted by software. Using EasyHost software, you can also write your own programs to control the lower computer according to the communication protocol.

The output power is 22W laser, it is a high-power laser, we added a heat sink under the laser module. The heat sink is composed of aluminum sheets and 3 cooling fans. Its fiber is pluggable, here we choose a 1000μm fiber. Let’s check it now.

Software Operation:

Click ‘Open COM’, the software links the lower computer control circuit of the laser. When starting the software for the first time, set the maximum current first, and set a maximum current value according to the laser test report. If the current is too large, it is easy to burn out the laser chip. For each laser, the maximum current must be set first.

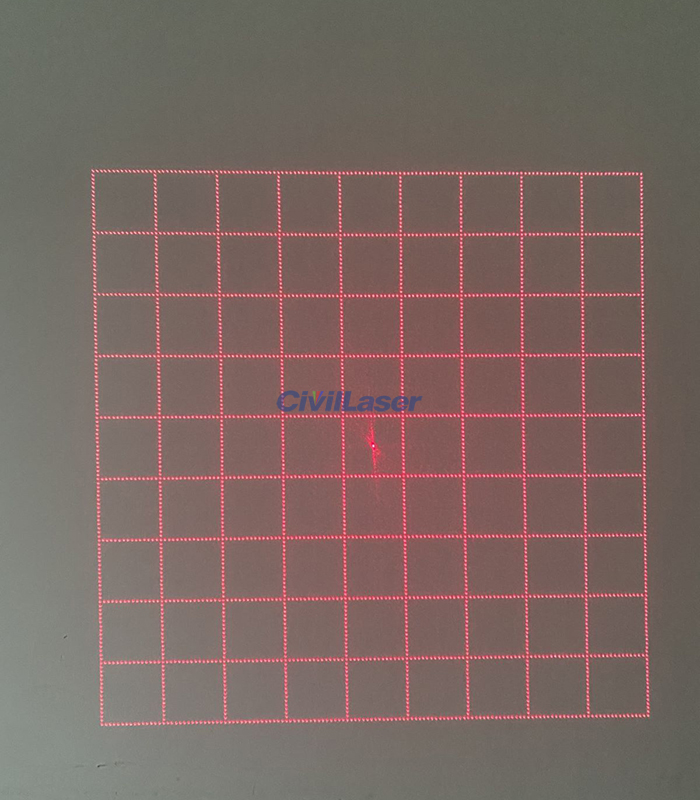

9*9 81 Grids Laser Diode Module Matrix

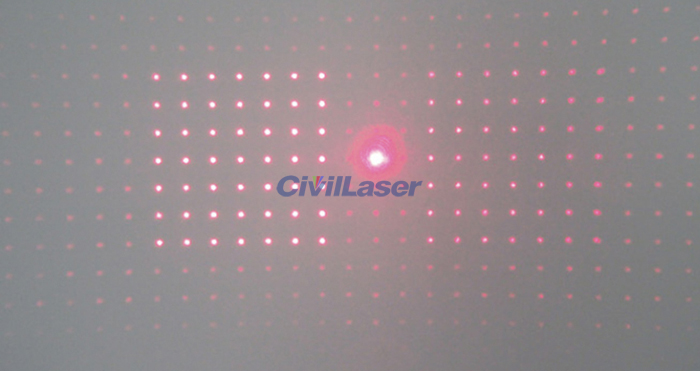

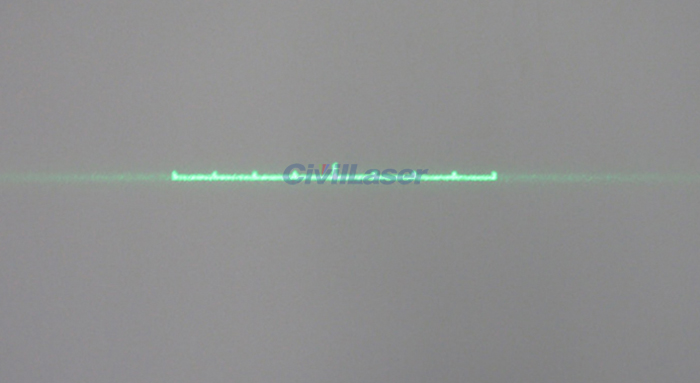

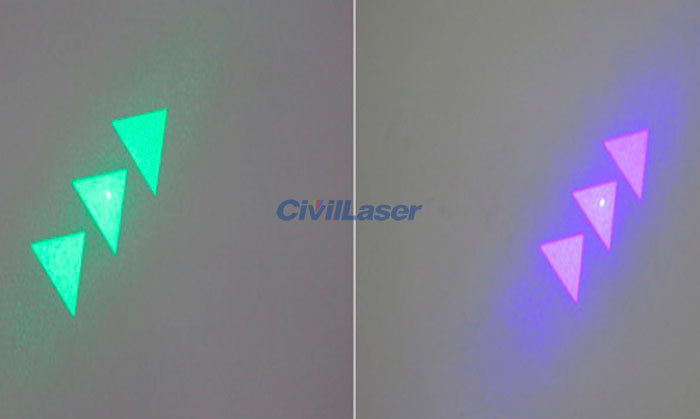

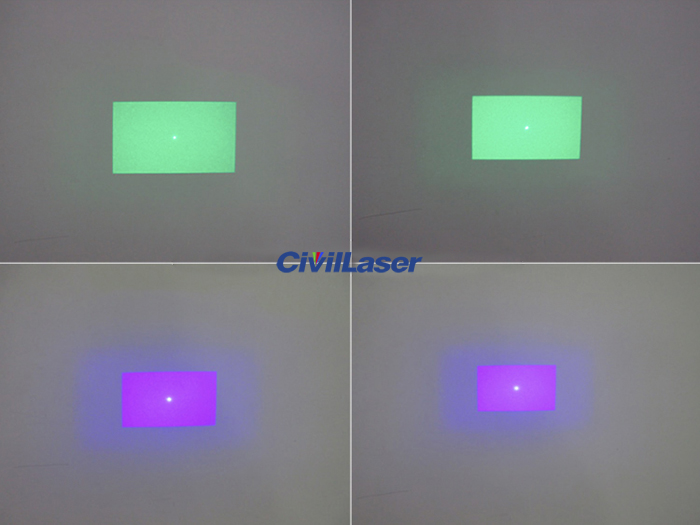

This is our best selling laser module. Its pattern is composed of 81 grids and a center point. The laser focal length is adjustable, which is convenient for different working distances. The red module is shown in the video, and the green laser and blue laser can also be customized. The video is real shot by mobile phone. Let’s check it now.

The actual effect projected on the wall.

In addition, We also have laser modules for many other patterns.

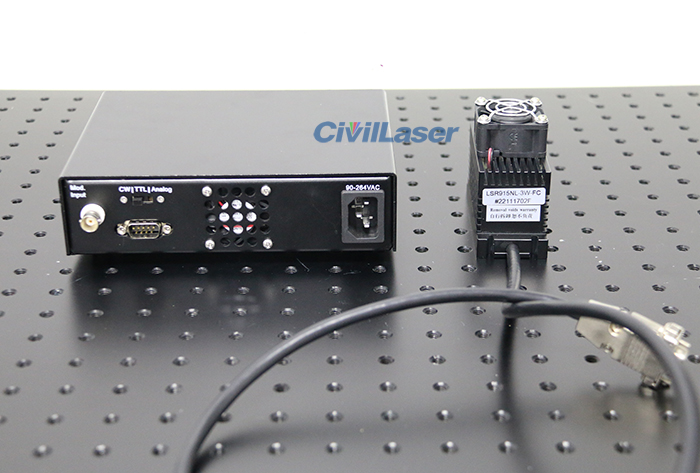

915nm 3W IR MM Fiber Coupled Laser System

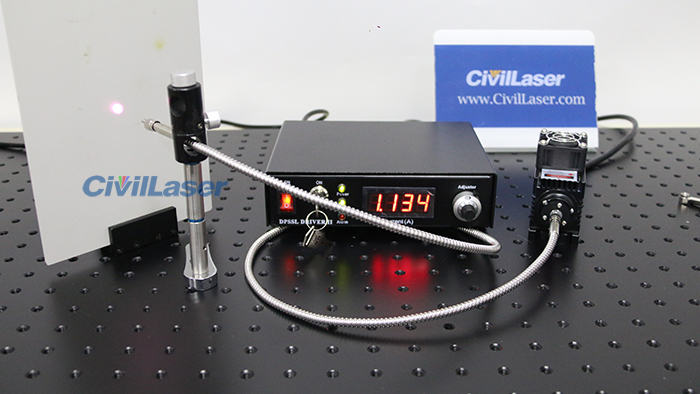

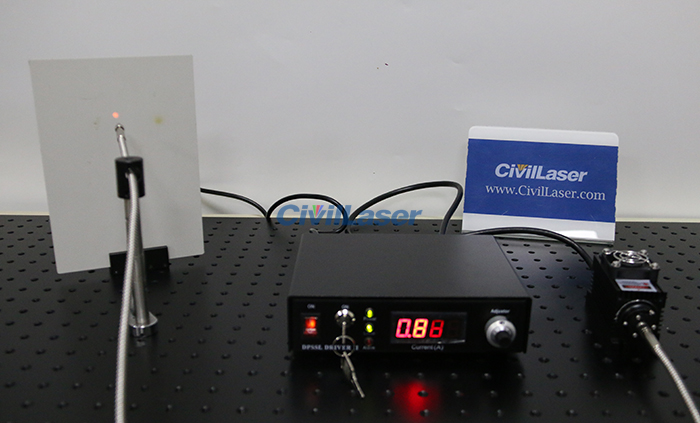

Usually we often see visible lasers, but few people will test infrared invisible lasers. Today we tested a 915nm infrared laser and its output power of 3000mW. Then when it is coupled through the fiber, what is the output power of the fiber end? Let’s check it now.

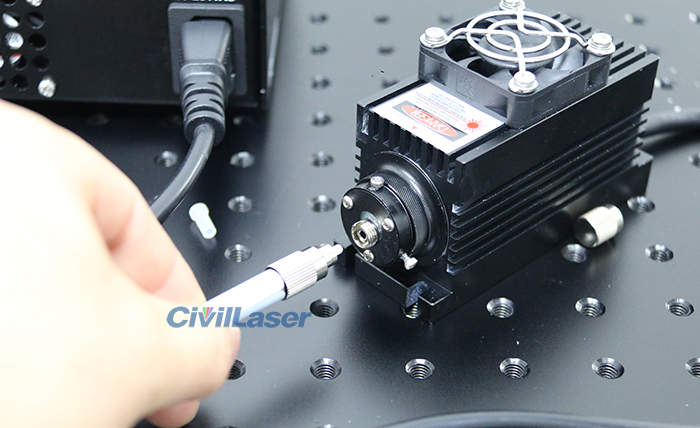

The optical fiber can be customized. 100μm~1000μm fiber is optional, the coupling efficiency of different fibers will be somewhat different. The larger the core diameter, the higher the coupling efficiency, usually the coupling efficiency is 80%~90 percent. In addition, the fiber length and interface also can be customzied. Here is 1000μm, SMA interface fiber.

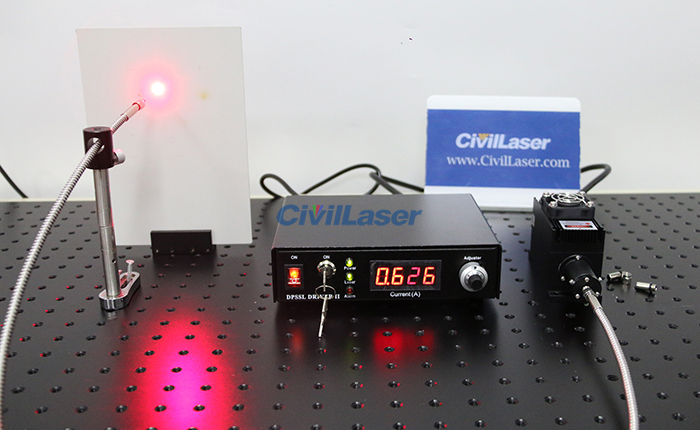

The output power of the laser is adjustable from 0 to 3000mW, which can be adjusted by the knob. It supports 3 working modes, CW/TTL/Analog, switch the working mode on the back of the laser power supply. In TTL/Analog modulation mode, an external modulation signal needs to be connected.

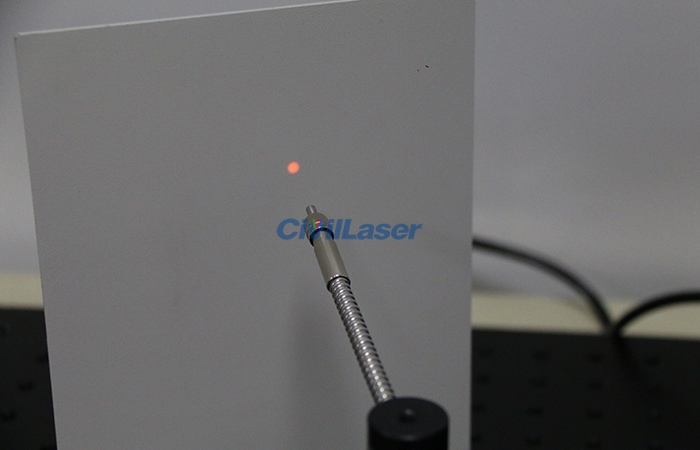

The 915nm laser is an infrared laser, invisible light, we use an infrared sensitive film to observe. Faint light spots can also be photographed with a camera.

772nm Fiber Laser CW Working Mode Operation Video

What we are going to demonstrate in today’s video is a 772nm 1W fiber coupled laser. The output power of the laser is adjustable from 0 to 1000mW, which can be adjusted by the knob. It supports 3 working modes, CW/TTL/Analog, switch the working mode on the back of the laser power supply. In TTL/Analog modulation mode, an external modulation signal needs to be connected.

The optical fiber is pluggable and customizable. The fiber core diameter,fiber length and interface can be customized according to customer needs. 100μm to 1000μm fiber is optional, the coupling efficiency of different fibers will be somewhat different. The larger the core diameter, the higher the coupling efficiency, usually the coupling efficiency is 80%~90%.

The 772nm laser is a near-infrared laser, and the light spot is dim.

660nm Red Semiconductor Laser Coupled Fiber Optic

What I’m going to talk about today is 660nm 1800mW fiber laser system. It supports 3 working modes, CW/TTL/Analog. In TTL/Analog modulation mode, an external modulation signal needs to be connected. In addition, the Lock crystal head cannot be pulled out. External signal Mod Input, no need to connect in CW working mode.

The optic fiber can be customized. Here is 1000μm SMA905 interface fiber. 100μm to 1000μm fiber is optional, the coupling efficiency of different fibers will be somewhat different. The larger the core diameter, the higher the coupling efficiency, usually the coupling efficiency is 80~90%.

To adjust the output power by adjusting the working current:

Turn the ‘Adjustor’ knob clockwise, when the current exceeds the minimum working current, the Laser indicator light turns green, and there is laser output at this time. When the ‘Adjustor’ is rotated clockwise to the end, it is the max working current and the max output power of the laser. In addition, the red STOP button is used for emergency stop, and it is not used under normal circumstances.

1615nm IR Invisible Fiber Laser Source

This is a 1615nm 200mW infrared fiber coupled laser source. The output power is 0~200mW adjustable by adjusting the working current. Turn the ‘Adjustor’ knob on the power supply clockwise, when the current exceeds the minimum working current, the Laser indicator light turns green, and there is laser output at this time. When the ‘Adjustor’ is rotated clockwise to the end, it is the max working current and the max output power of the laser.

The Optical fiber is removable. The optical fiber interface is FC/PC, and it can be customized. The 1615nm laser is an infrared laser, which cannot be observed by the human eye. We use an infrared sensitive film to observe the light spot.

450nm 1500mW Software Control Fiber Laser

Today we are talking about software-controlled laser system. This is 450nm blue fiber coupled laser source controlled by software. EasyHost is the control software. The connection between the laser and PC software adopts the communication protocol of RS232. The laser supports two working modes: CW/Modulation. When switching to Modulation, an external signal input is required. This is a fiber-coupled laser, and a free-space output laser can also be customized.

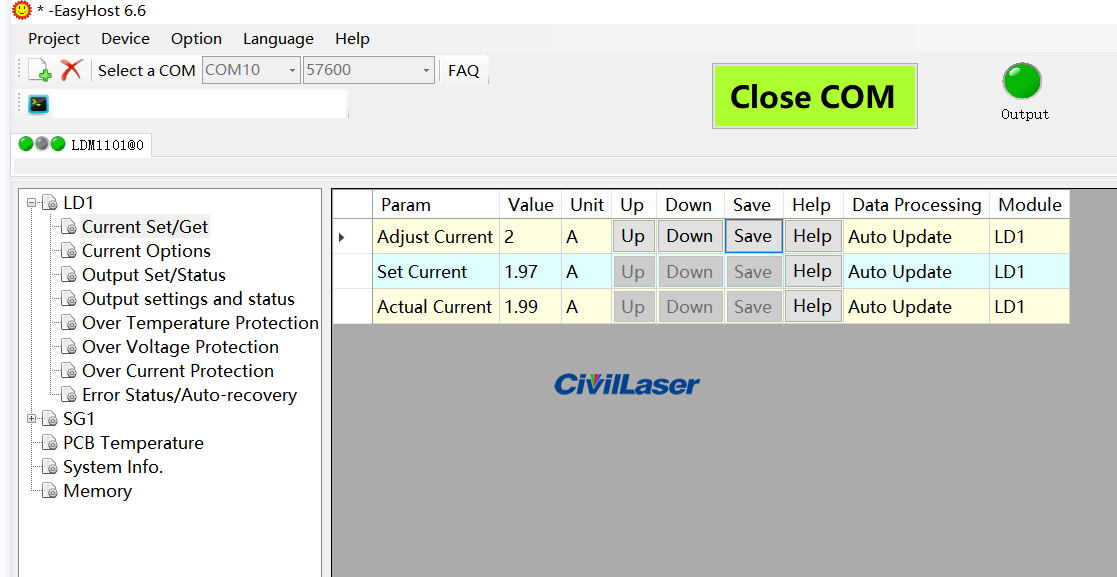

Software operation:

Click the [Open COM] button to connect the control circuit of the laser. Multiple laser working parameters can be viewed/set in the software. As a special reminder, it is necessary to set amaximum working current parameter according to the current laser, so as to avoid the later adjusted current being too high and damaging the laser.