Tag Archives: laser beam

Various wavelengths of the laser beam/ Laser Knowledge — CivilLaser

Various wavelengths of the laser beam/ Laser Knowledge — CivilLaser

1. Brightness: Green laser beam > Red laser beam > Blue-violet laser beam

2. Price: Blue-violet laser beam > Green laser > Red laser

3. Poly thermal performance (Burning feature): Blue-violet laser = Red laser > Green laser

4. Stability: Red laser = Blue-violet light > Green laser(green light influenced by the climate, cold environment to make

With, you need to warm up)

Laser module — The relationship between the power,brightness and working disance

Laser module — The relationship between the power,brightness and working disance

Laser Module — Knowledge (CivilLaser)

| Output power | Brightness Level | Best Working distance | Description |

|---|---|---|---|

| <5mw | Micro Light | < 0.5 meter | 1. In less than 0.5 meters.

2. Under the weak light environment. |

| <10mw | Low Light | < 1 meter | 1. In less than 1 meters.

2. Under the weak light environment. |

| <100mw | Middle Light | < 3 meters | 1. In less than 3 meters. 2. Under 8 fluorescent lights environment. You can see the laser beam. |

| <200mw | High Light | < 5 meters | 1. In less than 5 meters. 2. Under 30 fluorescent lights environment. You can see the laser beam. |

| >250mw | Ultra-high Light | < 8 meters | 1. In less than 8 meters. 2. In good light,under unlight scattering environment. You can see the laser beam.(Direct sunlight, unavailable) |

Laser beam class level & Laser Safety Classification

Laser Level:

ClassⅠ: <0.4mW

ClassⅡ: 0.4mW ~ 1mW

Class ⅢA: 1mW ~ 5mW

Class ⅢB: 5mW ~ 500mW

ClassⅣ: >500mW

Laser Safety Classification

According to its risk level to human body, with MPE (maximal possible effect) of light beam to eyes as a standard, it can be divided into Class I, II, III and IV. Laser product makers should stick the warning label with laser safety classification on the corresponding laser products.

Class I: low output laser (power < 0.4mW), the risk to human eyes and skin will not exceed MPE value under any conditions, even after focusing ion beam through optical system. The design safety can be guaranteed, no need special management. Typically used in CD players, CD-ROM equipment, geological prospecting equipment and laboratory analytical instruments etc..

Class II: low output visible laser (power 0.4mW-1mW), the reaction time of keeping eyes closed is 0.25S, light exposure calculated in this period should not more than MPE value. Usually the laser below 1mW can cause dizziness and make you unable to think, so you close your eyes to protect them, which is not totally safe. Don’t observe things directly in the beam, don’t light directly to others eyes with Class II laser and avoid the observation of Class II laser with telescope or the like. Typically used in classroom demonstration, laser pointer, pointing devices and distance measuring instruments etc..

Class III: mid output laser, if the beam shines directly into eyes, it will hurt the eyes, for some safety reasons, it is further divided into Class IIIA and Class and IIIB.

Class IIIA: the continuous laser of visible light, with a output laser beam of 1-5mW, the beam energy density should not be more than 25W/m﹣m, avoid the observation of Class IIIA laser with the telescope and the like, or it may increase the risk. There are lots of similarities of typical applications of Class IIIA and Class II, such as laser pointer and laser scanner etc..

Class III B: the continuous laser of 5-500mW light, which will cause danger if directly observing things in the beam. However, it is safe with the min. exposure distance of 13cm and max. exposure time of 10S. Class IIIB laser is typically applied in spectrometry and light entertainment etc..

Class IV: high output continuous laser (>500mW), it is higher than the Class III, which will cause fire, and its scattered reflection is also dangerous. Typically applied in surgical operation, research, cutting, welding and micro machining etc..

Safety measures on laser processing: it can ensure safety for some general household or office laser discs or laser printer or other applied machines, as the laser light will not go out to the external construction. In addition, functional device wouldn’t be provided to some lasers that the light won’t go out. If it happens, please refer to the following countermeasures.

(1) According to the level of laser devices, specialized personnel who have a sufficient knowledge and understanding of laser safety or hazard should guide in the laser treatment.

(2) Personnel producing lasers above Class III shall be competent on the basis of appropriate education of safe operation.

(3) Don’t view the light path directly if laser devices in action don’t emit laser light.

(4) When turning down the optical axis during the adjustment of laser resonator, the laser light will emit suddenly, so please always pay attention to the eye position when handling.

(5) If infrared light invisible to the eyes is adopted for large CO2 laser, people nearby should pay special attention to it.

(6) If reflected light or pot shoot light cannot be avoided, users can wear protective glasses when using lasers above Class III.

Different laser wavelengths, What are the shape of the laser spot?

Different laser wavelengths, What are the shape of the laser spot?

445nm is a multi-mode, rectangular beam;

405nm is an ellipse;

808.980,780,1064,635,650 are square spot;

The rest is almost round.

What is the usage of high quality of spot?

Professional research and detection will have high requirement on the spot quality, if only for entertainment, there is no practical significance.

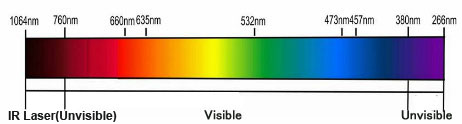

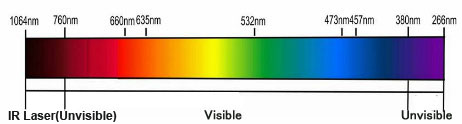

The relationship between laser wavelength and laser color

The relationship between laser wavelength and laser color

.jpg)