Tag Archives: laser beam

435nm 18W Blue Semiconductor Laser Fiber Output

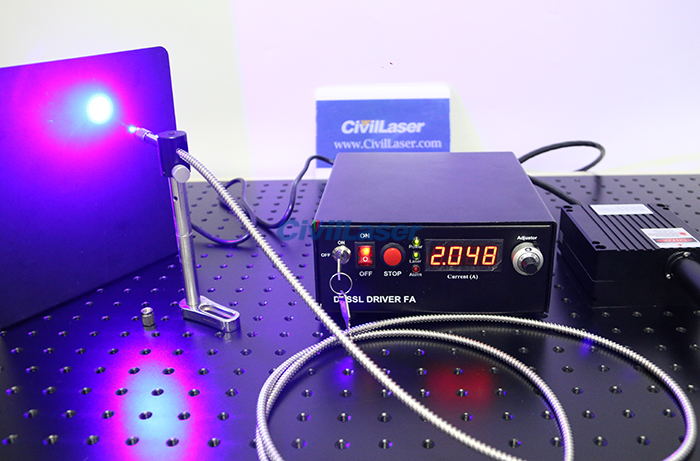

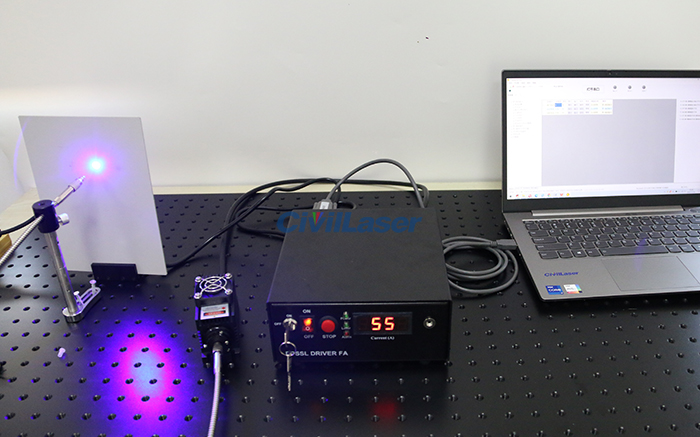

Today we are showing the 435nm fiber coupled laser. The power is 18W, and it is adjustable. The Adjustor button on the power supply is used to adjust the working current, and the laser output power can be adjusted by adjusting the current. The laser supports CW continuous working and Modulation working mode, which can be adjusted by the slider button on the back of the laser power supply. Next we demonstrate the CW working mode of this laser. Let’s check it now.

Laser output without fiber optic installed.

Here the optical fiber interface at the laser module end is FC/PC, align the buckle, insert the fiber, and tighten the fixing nut.

Laser output after installing the optical fiber.

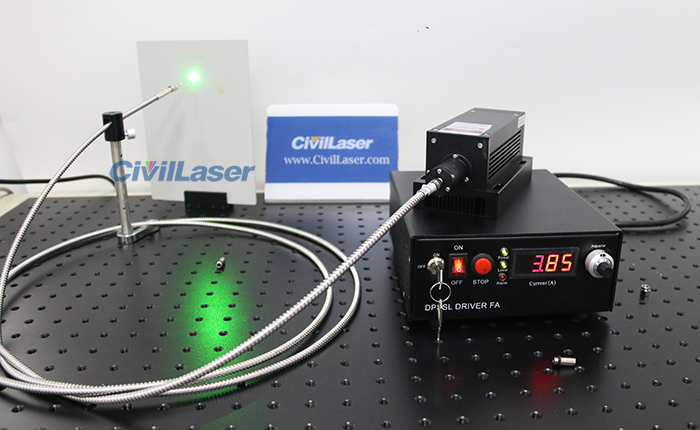

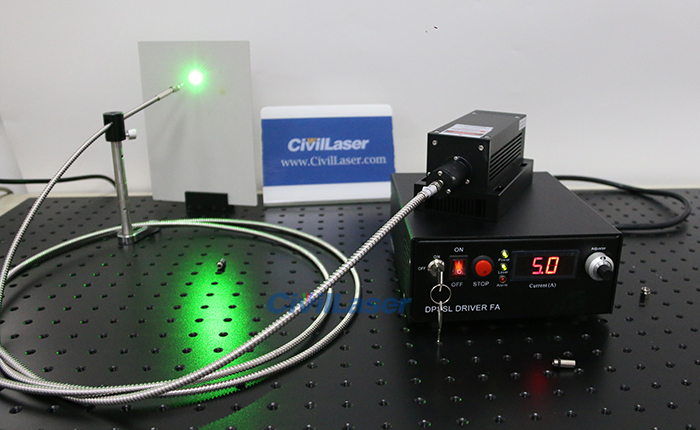

520nm 22W Lab Laser Fiber Output PC Control

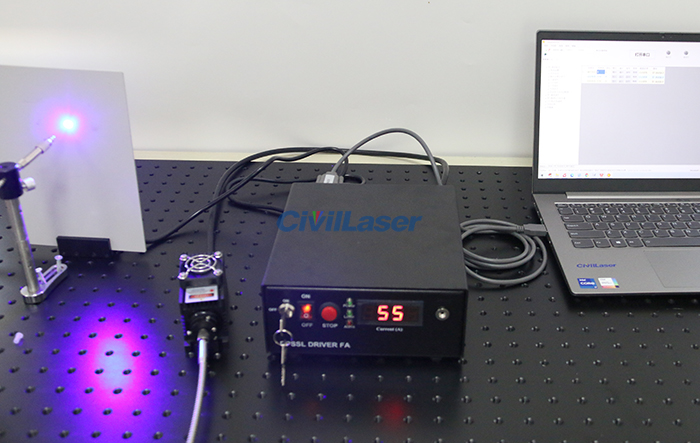

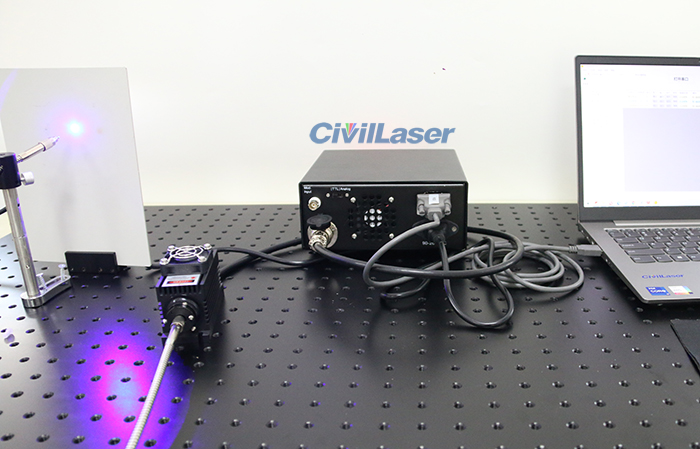

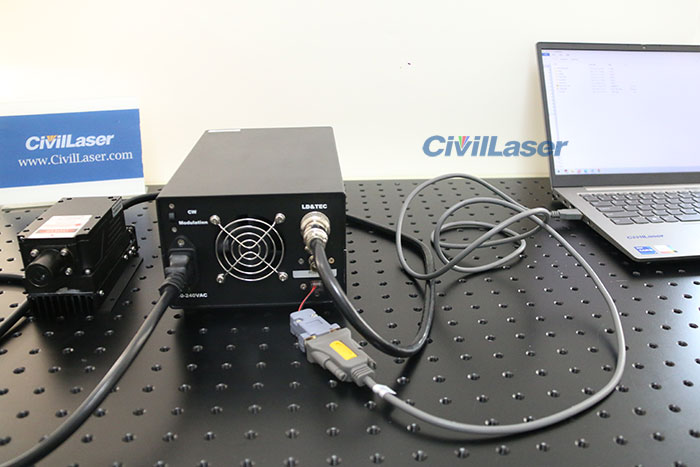

This is 520nm high power green fiber laser system. This laser adds software control. Use RS232-USB to connect the laser and computer software.The laser output power can be adjusted by software. Using EasyHost software, you can also write your own programs to control the lower computer according to the communication protocol.

The output power is 22W laser, it is a high-power laser, we added a heat sink under the laser module. The heat sink is composed of aluminum sheets and 3 cooling fans. Its fiber is pluggable, here we choose a 1000μm fiber. Let’s check it now.

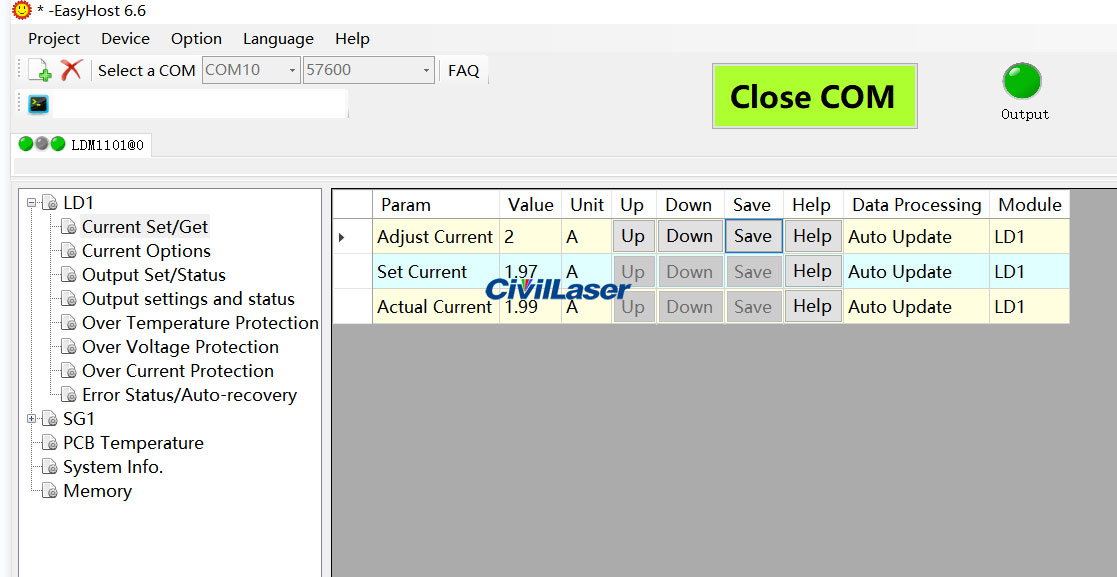

Software Operation:

Click ‘Open COM’, the software links the lower computer control circuit of the laser. When starting the software for the first time, set the maximum current first, and set a maximum current value according to the laser test report. If the current is too large, it is easy to burn out the laser chip. For each laser, the maximum current must be set first.

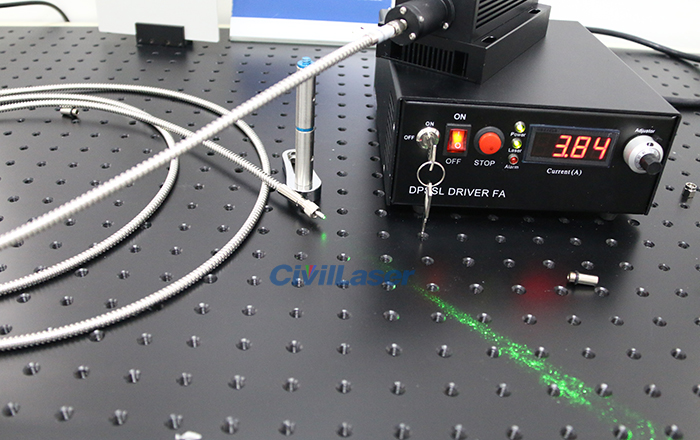

660nm Red Semiconductor Laser Coupled Fiber Optic

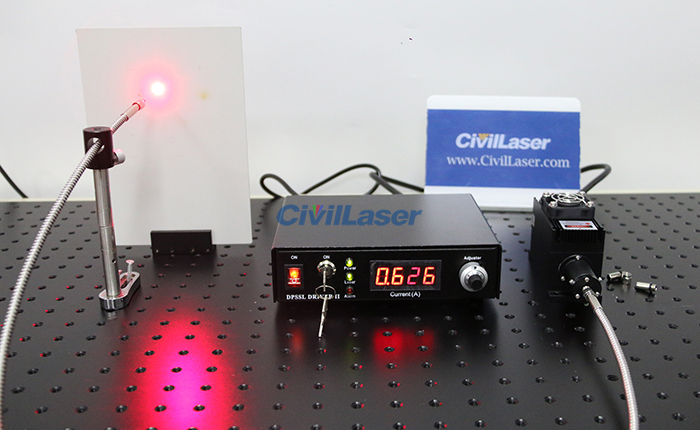

What I’m going to talk about today is 660nm 1800mW fiber laser system. It supports 3 working modes, CW/TTL/Analog. In TTL/Analog modulation mode, an external modulation signal needs to be connected. In addition, the Lock crystal head cannot be pulled out. External signal Mod Input, no need to connect in CW working mode.

The optic fiber can be customized. Here is 1000μm SMA905 interface fiber. 100μm to 1000μm fiber is optional, the coupling efficiency of different fibers will be somewhat different. The larger the core diameter, the higher the coupling efficiency, usually the coupling efficiency is 80~90%.

To adjust the output power by adjusting the working current:

Turn the ‘Adjustor’ knob clockwise, when the current exceeds the minimum working current, the Laser indicator light turns green, and there is laser output at this time. When the ‘Adjustor’ is rotated clockwise to the end, it is the max working current and the max output power of the laser. In addition, the red STOP button is used for emergency stop, and it is not used under normal circumstances.

450nm 1500mW Software Control Fiber Laser

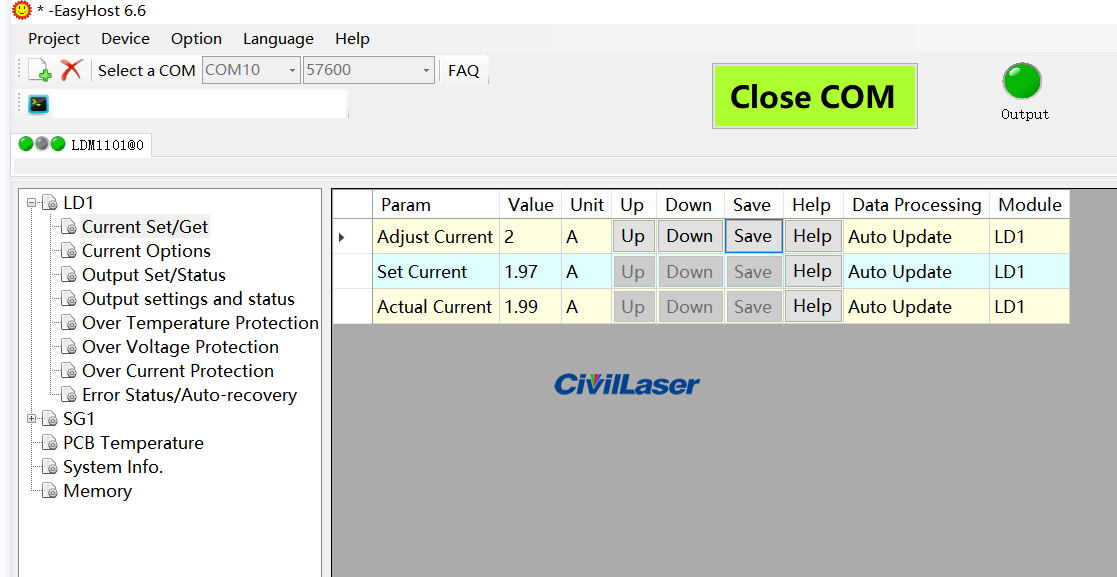

Today we are talking about software-controlled laser system. This is 450nm blue fiber coupled laser source controlled by software. EasyHost is the control software. The connection between the laser and PC software adopts the communication protocol of RS232. The laser supports two working modes: CW/Modulation. When switching to Modulation, an external signal input is required. This is a fiber-coupled laser, and a free-space output laser can also be customized.

Software operation:

Click the [Open COM] button to connect the control circuit of the laser. Multiple laser working parameters can be viewed/set in the software. As a special reminder, it is necessary to set amaximum working current parameter according to the current laser, so as to avoid the later adjusted current being too high and damaging the laser.

532nm 1W DPSS TEM00 Lab Laser

It is 532nm DPSS laser source. This laser source can be controlled by software. The connection of the laser and the PC software, using the RS232 communication protocol. The laser supports two modes of operation CW/Modulation, and an external signal input is required when switching to Modulation. Here is the free space output, and it is also possible to customize the fiber-coupled laser. Let’s check it now.

Software operation.

Click the [Open COM] button to connect the control circuit on the laser.

Multiple laser operating parameters can be viewed/set in the software.

As a special reminder, it is necessary to set a maximum working current parameter according to the current laser first, so as to avoid the current of the later regulation being too high and damaging the laser.

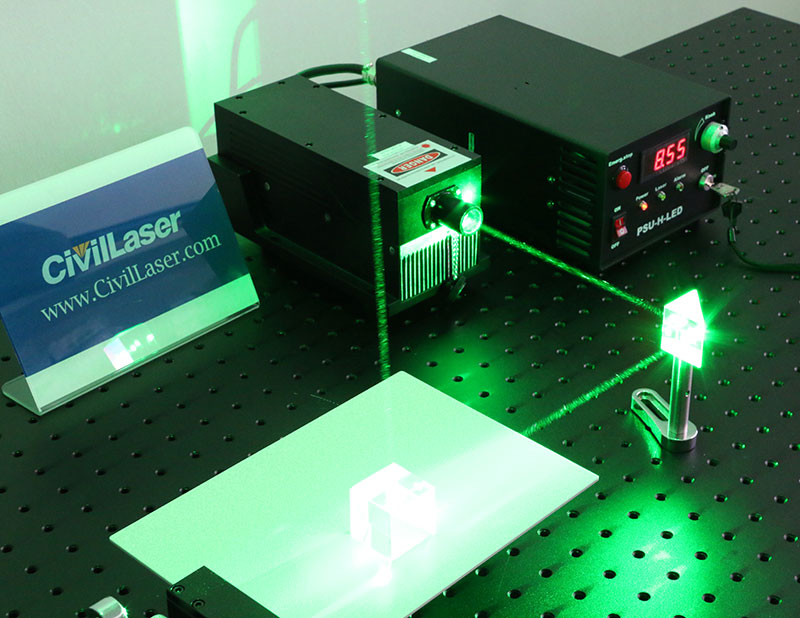

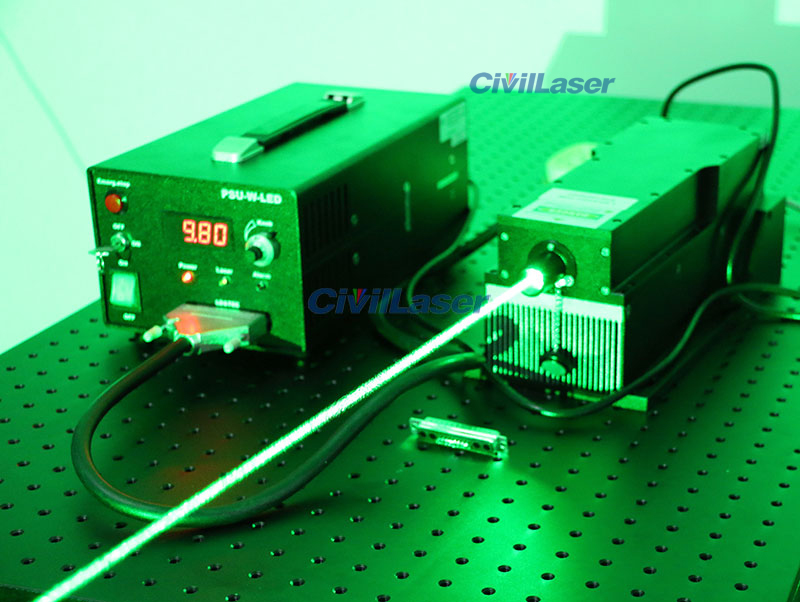

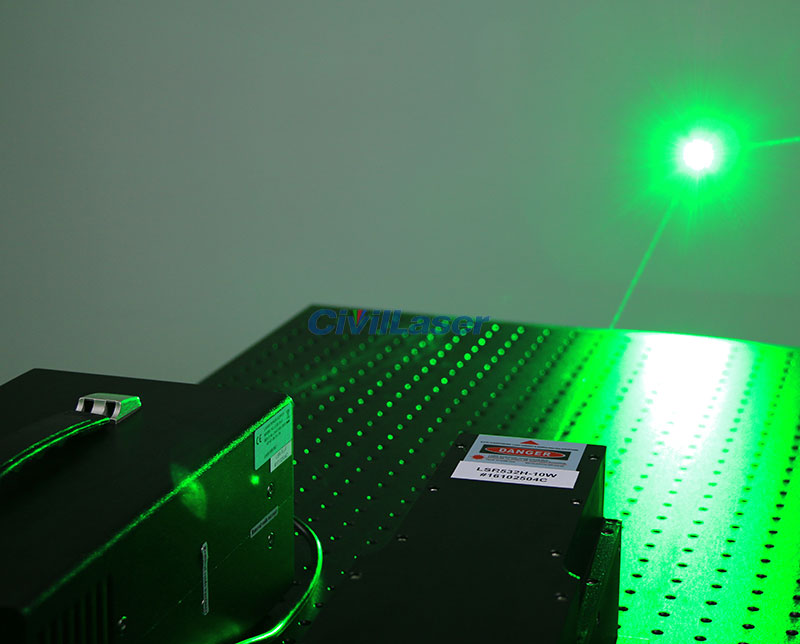

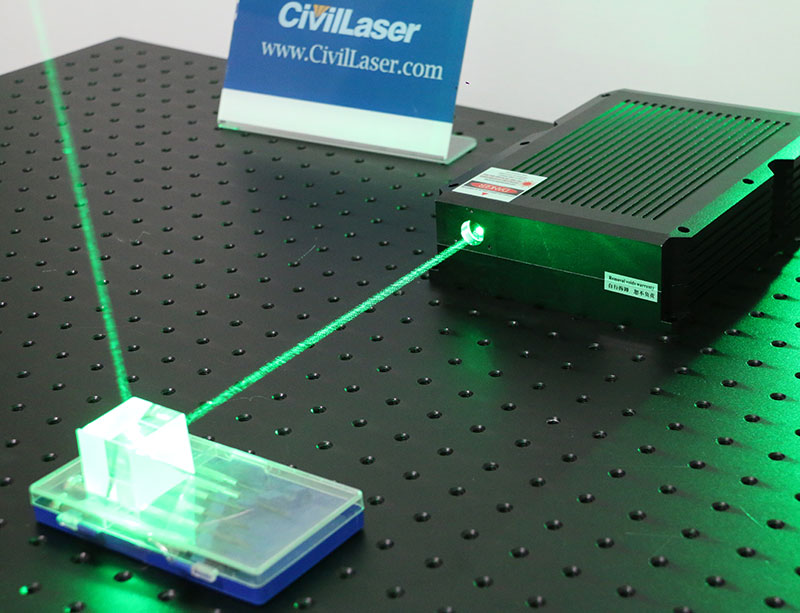

532nm DPSS Laser VS 520nm Semiconductor Laser

532nm and 520nm are both common green lasers in the laboratory. The difference is that one is a diode pumped solid state(DPSS) laser and the other is a semiconductor laser.

532nm is a commonly used wavelength in dpss laser. DPSS lasers have advantages in compactness and efficiency over other types, and high power DPSS have replaced ion lasers and flashlamp-pumped lasers in many scientific applications, and are now appearing commonly in green and other color laser pointers.

The choice of the semiconductor material determines the wavelength of the emitted beam, which in today’s laser diodes range from infra-red to the UV spectrum. Laser diodes are the most common type of lasers produced, with a wide range of uses that include fiber optic communications, barcode readers, laser pointers, CD/DVD/Blu-ray disc reading/recording, laser printing, laser scanning and light beam illumination. With the use of a phosphor like that found on white LEDs, Laser diodes can be used for general illumination.

520nm 12W semiconductor laser.

Custom fiber coupling is available for either 532nm dpss laser or 520nm semiconductor lasers. Please go to CivilLaser for details.

405nm Semiconductor Laser 12W Powerful Laser Source

This is a 405nm 12W blue-violet laser System. It is high power solid state laser with a heat sink installed at the bottom of the laser module. The radiator is aluminum with 2 cooling fans. Configuring a heat sink can effectively extend the continuous working time of the laser. There are 3 working modes on the back of the laser power supply: CW/TTL/Analog. The output power of the 0~12W laser can be adjusted by the Adjustor rotary button.

The 405nm 12W laser needs a collection of multiple LDs to have such a high power, so the spot mode is also multimode.

The 405nm laser is a blue-violet laser, which is close to ultraviolet invisible light. The 12W laser is not very dazzling to the naked eye. But the energy is very strong, please wear laser safety glasses when operating.

CivilLaser have mature production technology, stable quality and short production cycle.

520nm 2800mW Green Diode laser Lab Laser System

This is a 520nm 2800mW green laser system. The laser supports 3 working modes: CW, TTL, Analog. In addition, the Lock crystal head cannot be pulled out. External signal Mod Input, no need to connect in CW working mode. It is free space output by default, fiber-coupled output can be customized.

The laser output power can be adjusted by adjusting the operating current. In addition, the red STOP button is used for emergency stop, and it is not needed under normal circumstances.

The 520nm 2800mW green semiconductor laser beam.

543nm Green Solid State Laser with SMA905 Optical Fiber

This is a 543nm solid state laser system. The output power is 100mW, it can be adjusted by the rotary button on the power supply. The red button is the power switch. The key is a laser switch. The middle LCD shows the current working current. The rotary button on the right is to adjust the current size.

There are 3 working modes for the laser to choose from. Select the working mode CW/TTL/Analog by the sliding button on the back of the power supply.

This laser coupled a 1000μm, 3 meters in length, SMA905 interface fiber, and its can be customized.

The effect of laser output from the fiber port.

High Power Laser 18W 455nm Blue Laser Source

It is 455nm 18W blue laser system. The laser head is equipped with a heat sink. The heat sink has 3 cooling fans, which can effectively extend the continuous working time of the high-power laser. There is a small power interface on the side of the data cable close to the laser head for the cooling fan. In addition, the Lock crystal head cannot be pulled out. External signal Mod Input, no need to connect in CW working mode.

This is a power tunable laser by adjusting the current. Turn the ‘Adjustor’ knob clockwise to adajust the current, when the current exceeds the minimum working current, the Laser indicator turns green, and there is laser output at this time. ‘Adjustor’ rotates clockwise to the end, which is the maximum working current and the maximum output power of the laser. In addition, the red STOP button is used for emergency stop, and it is not needed under normal circumstances.

Safety reminder:

Wear laser safety glasses when operating high-power lasers. It is forbidden to irradiate human eyes and skin with laser light.