Category Archives: Civil Laser

300mW 2200nm Infrared Fiber Optic Lab Laser System

The 2200nm multimode fiber-coupled laser is fiber-coupled with a 2200nm semiconductor laser to obtain fiber output. The coupled fiber output laser power stability is good, the spot pattern can be improved, and the collimated beam can meet the demand for high beam requirements.

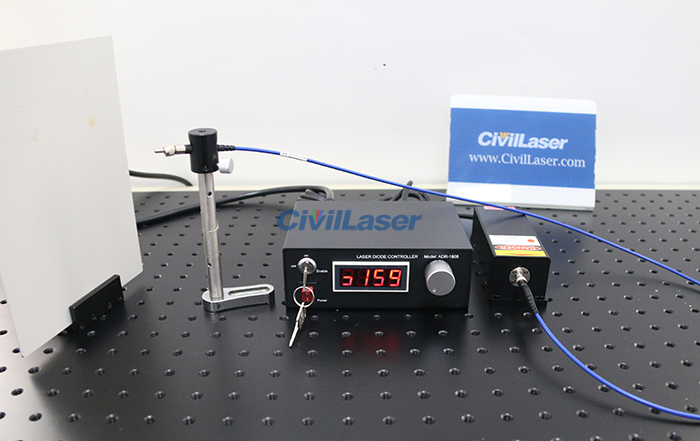

It is a 2200nm 300mW laser system with 400μm fiber. The optical fiber is pluggable, and it’s interface can be customized according to customer needs. It supports two working modes: CW and Modulation. The laser output power is adjustable by rotating the silver-white rotary button. The middle display shows the magnitude of the current. The higher the current, the higher the output laser power.

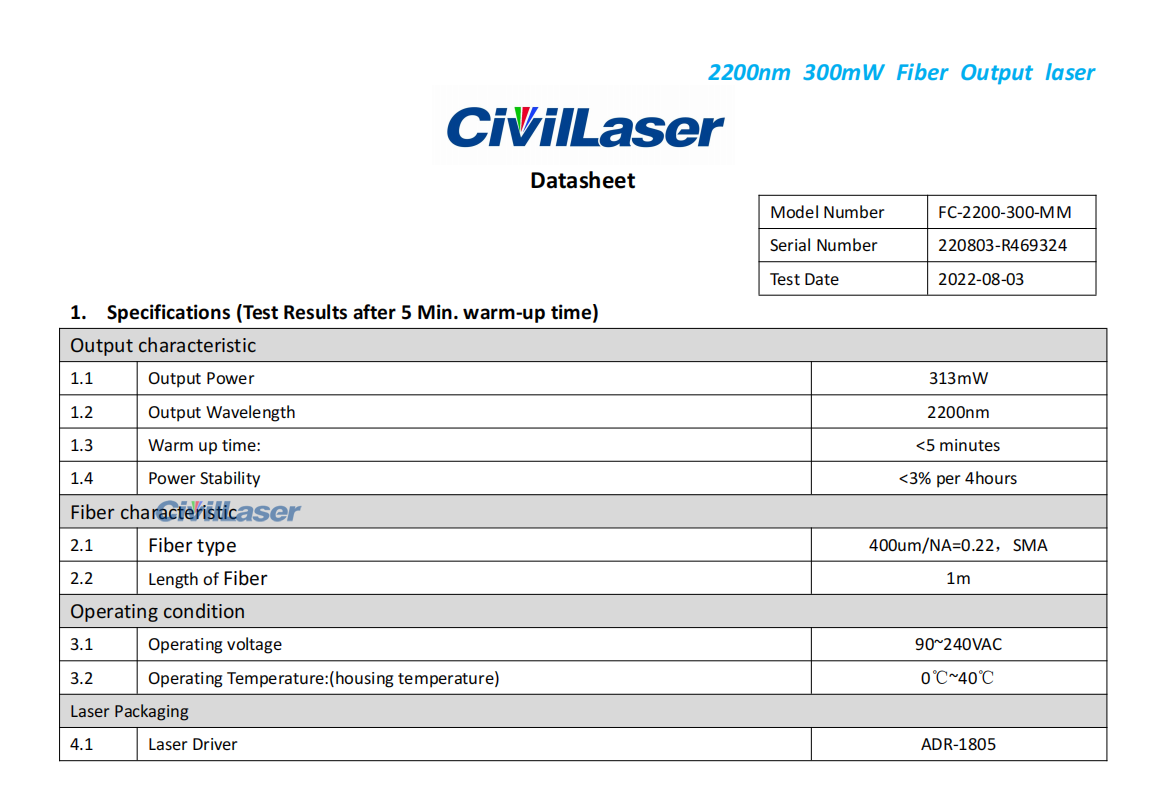

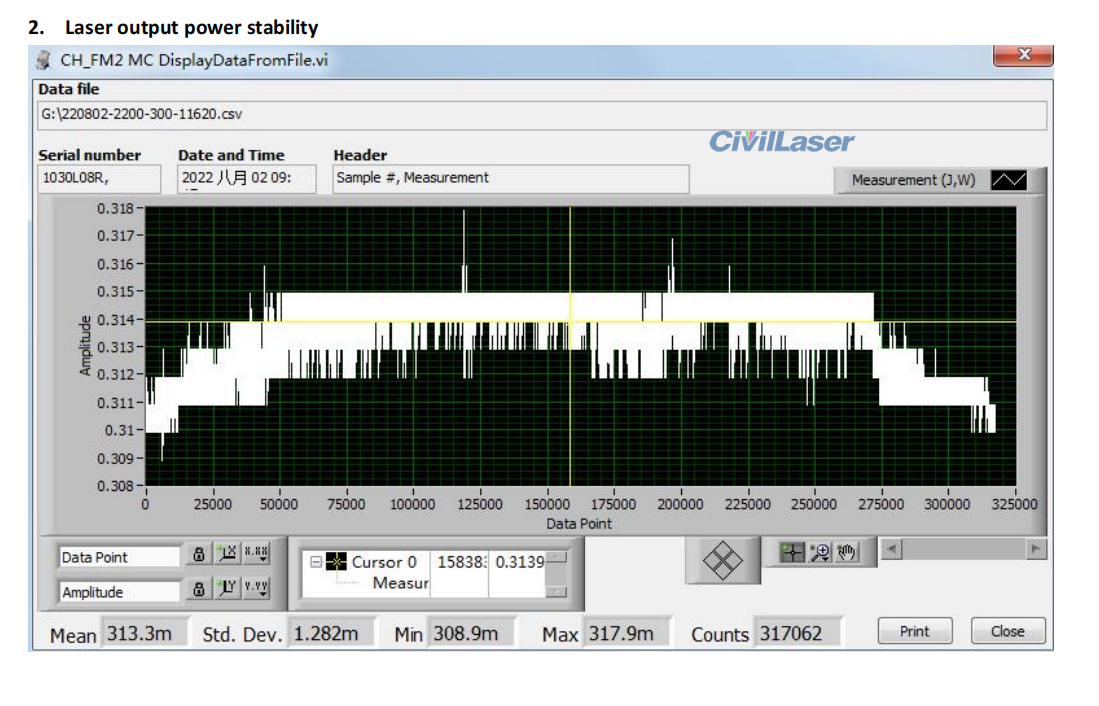

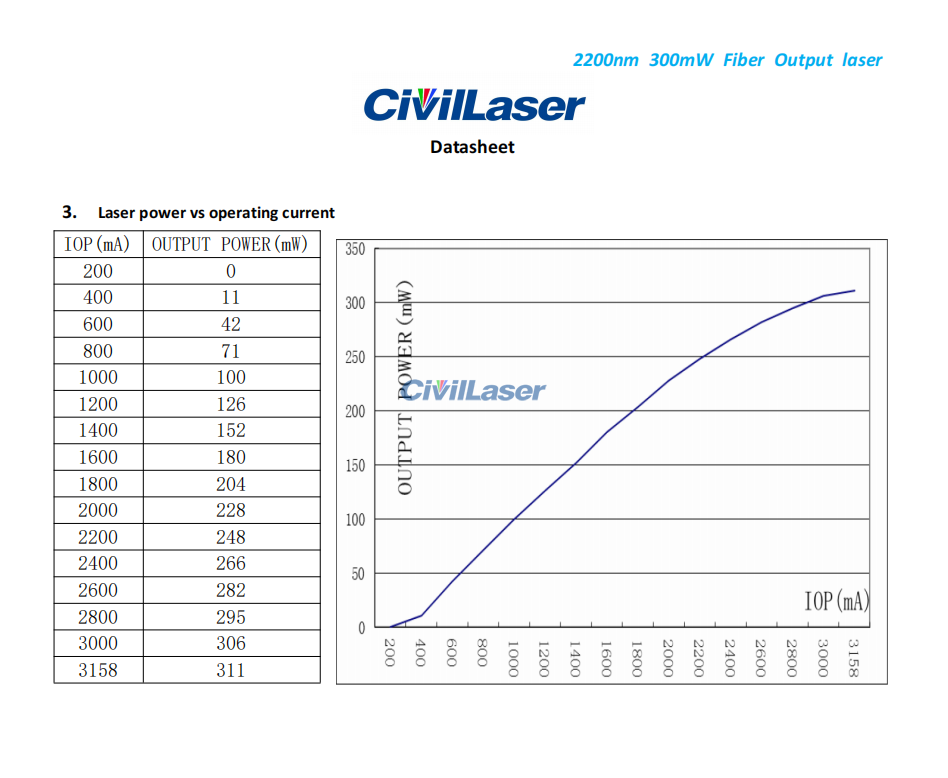

The test report for the 2200nm laser.

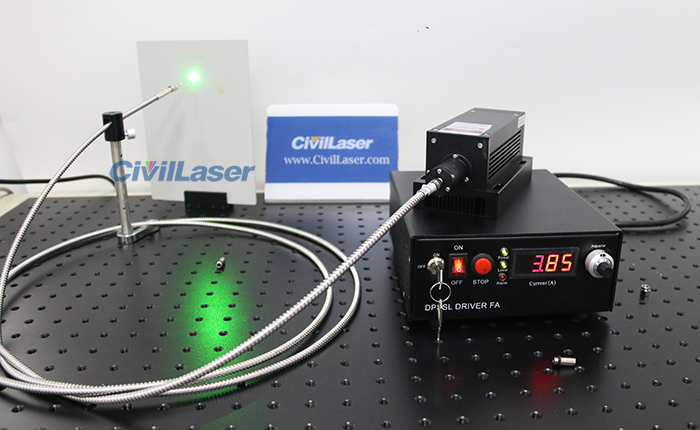

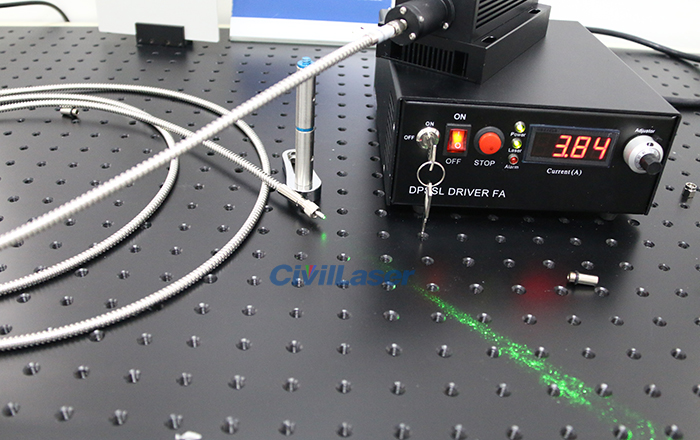

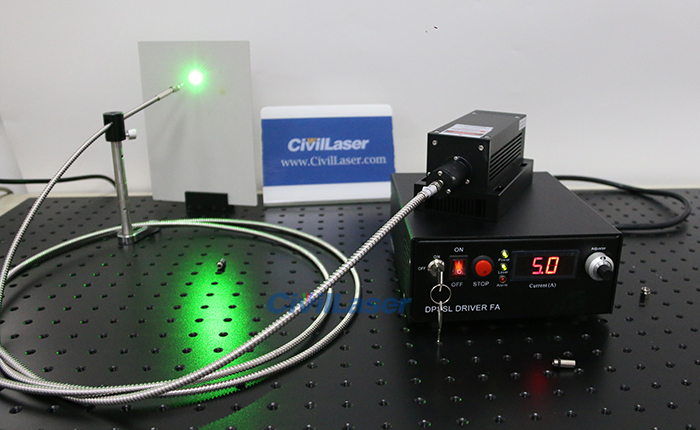

520nm 2800mW Green Diode laser Lab Laser System

This is a 520nm 2800mW green laser system. The laser supports 3 working modes: CW, TTL, Analog. In addition, the Lock crystal head cannot be pulled out. External signal Mod Input, no need to connect in CW working mode. It is free space output by default, fiber-coupled output can be customized.

The laser output power can be adjusted by adjusting the operating current. In addition, the red STOP button is used for emergency stop, and it is not needed under normal circumstances.

The 520nm 2800mW green semiconductor laser beam.

543nm Green Solid State Laser with SMA905 Optical Fiber

This is a 543nm solid state laser system. The output power is 100mW, it can be adjusted by the rotary button on the power supply. The red button is the power switch. The key is a laser switch. The middle LCD shows the current working current. The rotary button on the right is to adjust the current size.

There are 3 working modes for the laser to choose from. Select the working mode CW/TTL/Analog by the sliding button on the back of the power supply.

This laser coupled a 1000μm, 3 meters in length, SMA905 interface fiber, and its can be customized.

The effect of laser output from the fiber port.

976nm Invisible Laser 9W High Power Laser Coupled Fiber

What we are talking about today is the 976nm 9W fiber coupled laser. The laser power is adjustable, and the laser output power is controlled by button. It is equipped with 105μm optical fiber output by default. It can be customized software control, use RS232-USB data cable to connect computer software.

976nm is an infrared laser, invisible to the naked eye, and a faint red light spot can be photographed with an ordinary camera.

Instructions for operation:

Press the middle square button to enter the setting state.

The laser adjusts the output power by adjusting the current.

The left and right arrows select data bits.

The up and down arrows adjust the size of the value on the data bit.

Finally, press the square button to complete the setting.

When the key is turned ON, the Active indicator lights up, the laser is officially working, and there is laser output.

High-power laser light source is based on high-performance semiconductor laser chip, 105/125μm fiber coupling output. The professionally designed constant current drive and temperature control circuit ensure the safe and stable operation of the laser. Some models have wavelength locking, and the spectral stability can be better than ±3nm. Ideal for medical research, fiber laser pumping, and other production testing. Desktop or module packaging can be provided, and host computer monitoring software can be provided.

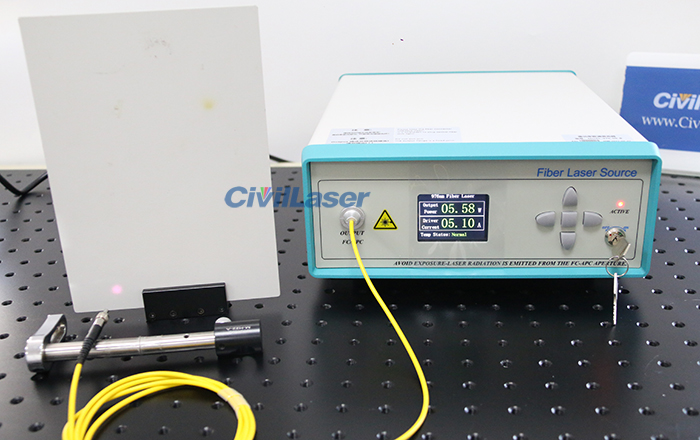

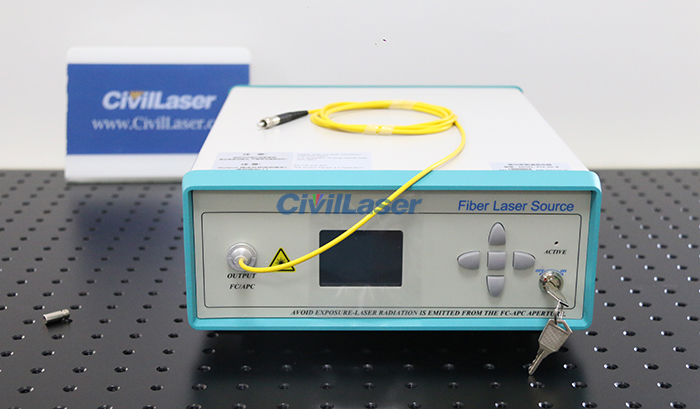

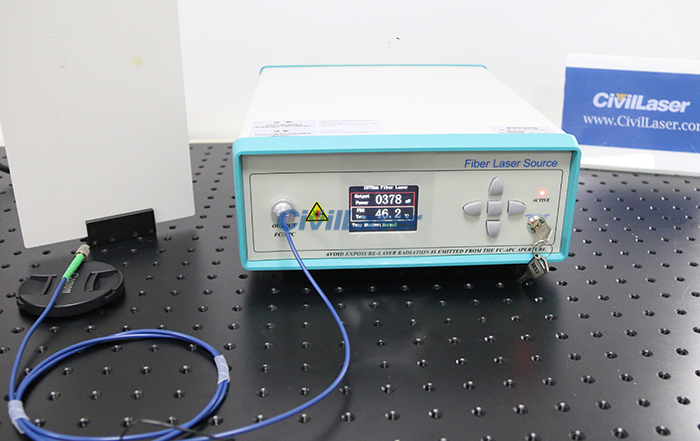

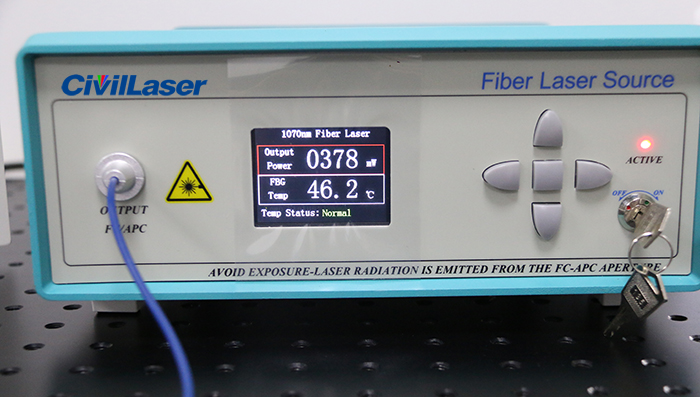

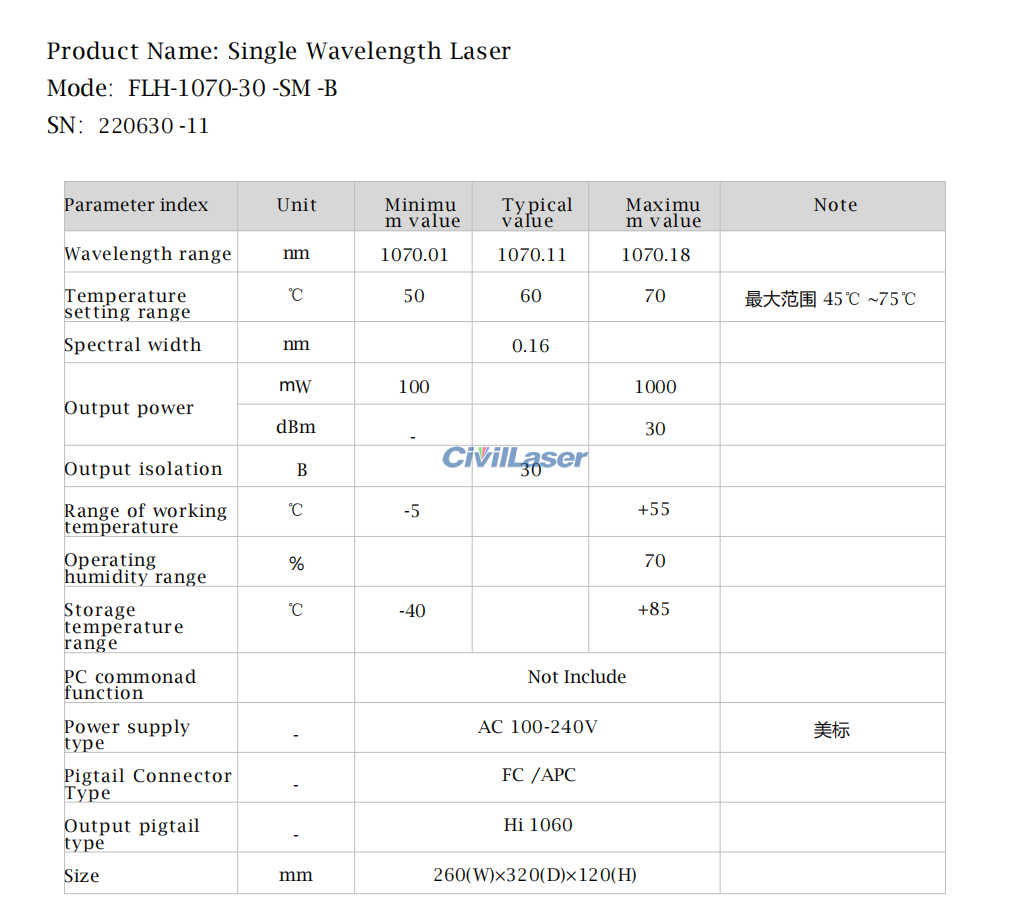

1070nm Single-mode Fiber Laser Source Benchtop

This laser adopts all-fiber laser technology, professionally designed and driven temperature control circuit and control to ensure the safe operation of the laser and stable laser output power and spectrum. It is suitable as a seed laser for higher power laser systems, and can also be used for production testing of optical fiber devices.

This is 1070nm SM fiber laser system. The maximum power is 1W, 10%~100% power can be adjusted, adjusted by button, the adjustment accuracy is 1mW. You can adjust the wavelength by adjusting the temperature. This is a custom function and is not supported by default. By default, the laser is controlled by the button, and it can also be controlled by custom software, using the RS232-USB data cable to link the computer software.

This laser coupled singlemode fiber, the output of PM fiber can be customized. With LCD screen, it can display the current power and the currently set temperature.

Adjust the laser output power and laser wavelength by button. Press the middle square button to start the setup mode. The left and right arrows switch whether to set the laser output power or the temperature. The up and down arrows are used to adjust the size of the corresponding parameters. After the setting is complete, turn the switch key to ON. The Active indicator lights up and the laser starts to output.

This is the test data report.

1550nm Nanosecond Pulse Fiber Ultra-fast Laser Module

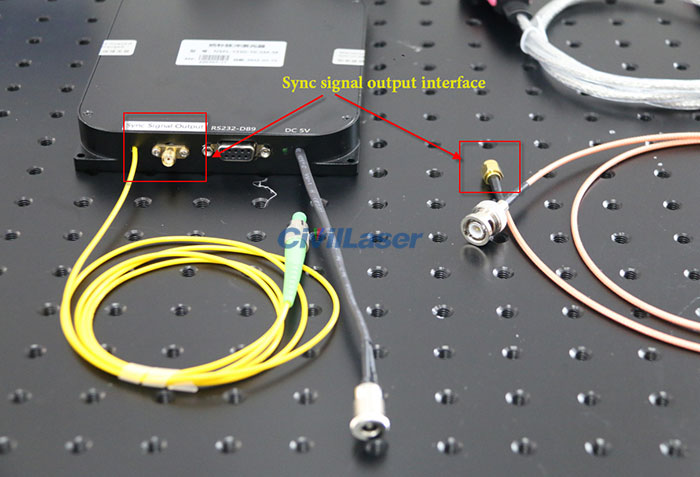

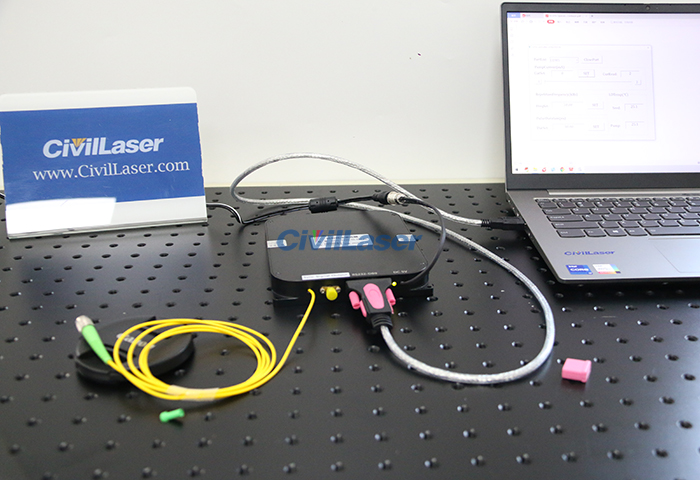

This is 1550nm nanosecond laser module with DC 5V power adapter. Single-mode fiber output, peak power is 10W. It can output synchronous electrical signal. The built-in trigger is used by default, and the signal frequency and signal pulse width are set by software.

This nanosecond laser is controlled by software. Three parameters of current, repetition frequency and pulse width can be set. The maximum repetition rate is 100kHz. The maximum pulse width is 30 nanoseconds.

Simply check whether the laser is outputting normally, the 1550nm infrared laser spot can be seen on the infrared photosensitive film, and the laser is working normally.

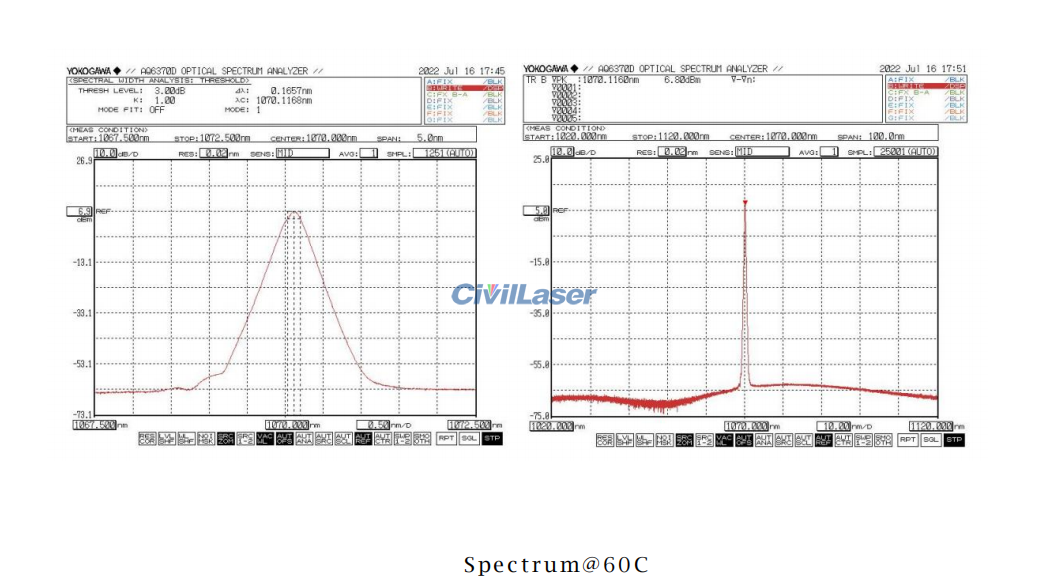

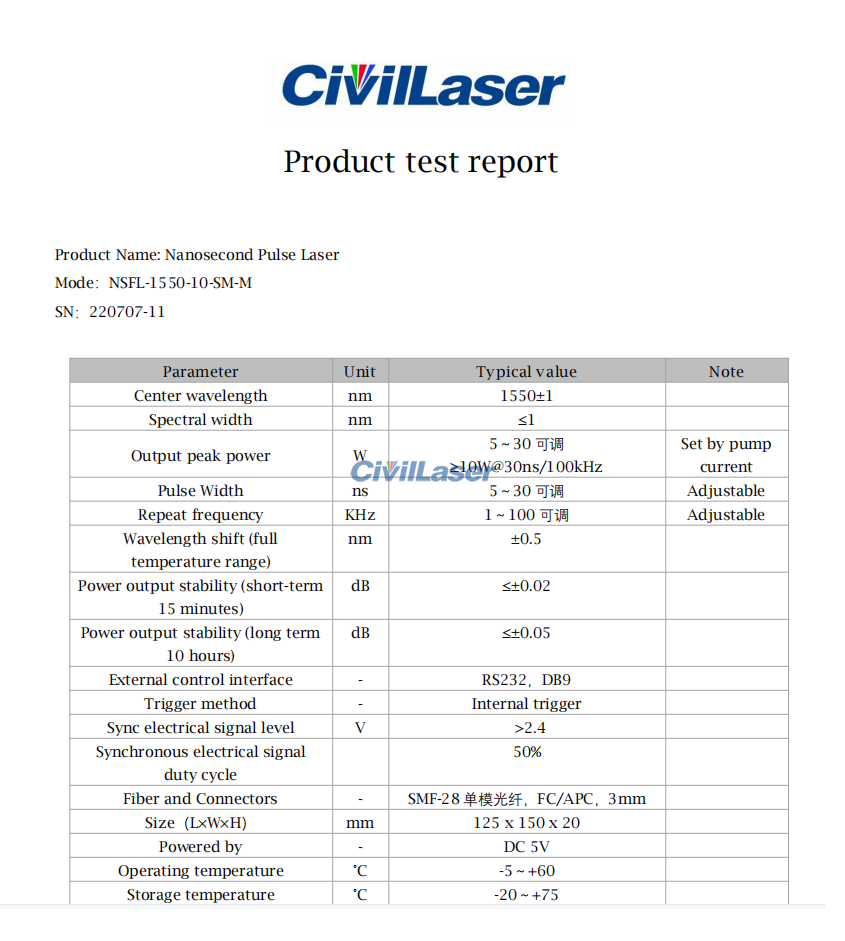

This is a test data report for the nanosecond laser module.

1064nm 15W Semiconductor Laser with Radiator Extend the Working Time

This is a laser system that adjusts the power by adjusting the current. To adjust the current, turn the ‘Adjustor’ knob clockwise, when the current exceeds the min working current, the Laser indicator turns green, and there is laser output. ‘Adjustor’ rotates clockwise to the end, which is the max working current and the max output power of the laser. In addition, the red STOP button is used for emergency stop, and it is not needed under normal circumstances. Let’s check it now.

This is a 1064nm 15W high power infrared laser. An aluminum heat sink is installed under the laser module, which can effectively extend the continuous working time. The radiator is equipped with two cooling fans. There is a small power interface on the side of the data cable close to the laser head for the cooling fan. In addition, the Lock crystal head cannot be pulled out. External signal Mod Input, no need to connect in CW mode. The IR laser supports 3 working modes: CW/TTL/Analog. The above video demonstrates CW working mode.

1064nm is invisible to the human eye. We use an infrared photosensitive film to view the light spot.

Safety reminder:

Wear laser safety glasses when operating high-power lasers.

Laser irradiation of human eyes and skin is prohibited.

880nm 20W Fiber Laser Source NIR Invisiable Laser

This is 880nm 20W high power infrared laser. A fiber coupling interface is added to the laser output port, which can be inserted into a fiber. A cooling device is added at the bottom of the laser module, which is composed of aluminum sheet and cooling fans. The laser supports CW continuous work and modulation work mode, which can be adjusted by the slider button on the back of the laser power supply.

The optical fiber is pluggable, the default fiber interface is FC/PC, and the fiber interface can be customized. The Adjustor button on the power supply is used to adjust the working current, so as to adjust the laser output power. Let’s check it now.

The 880nm laser is a near-infrared laser, basically invisible, only a faint red dot can be seen on the light shield.

1310nm 20mW PM Fiber DFB Laser Source Benchtop

This is a 1310nm 20mW infrared laser coupled optical fiber. The fiber is PM1310 polarization-maintaining fiber, and SMF-28e single-mode fiber can also be customized. In addition, the single-mode fiber coupling interface is a consumable part, we make it into a fixed state and cannot be plugged or unplugged. The power of the laser output can be adjusted by the button, and the adjustment accuracy is 0.1mW. The back of the laser has an RS232 interface, and software control mode can be added.

1310nm single-wavelength laser light source uses DFB semiconductor laser chip, polarization-maintaining fiber output, professionally designed drive circuit and TEC control to ensure the safe and stable operation of the laser.

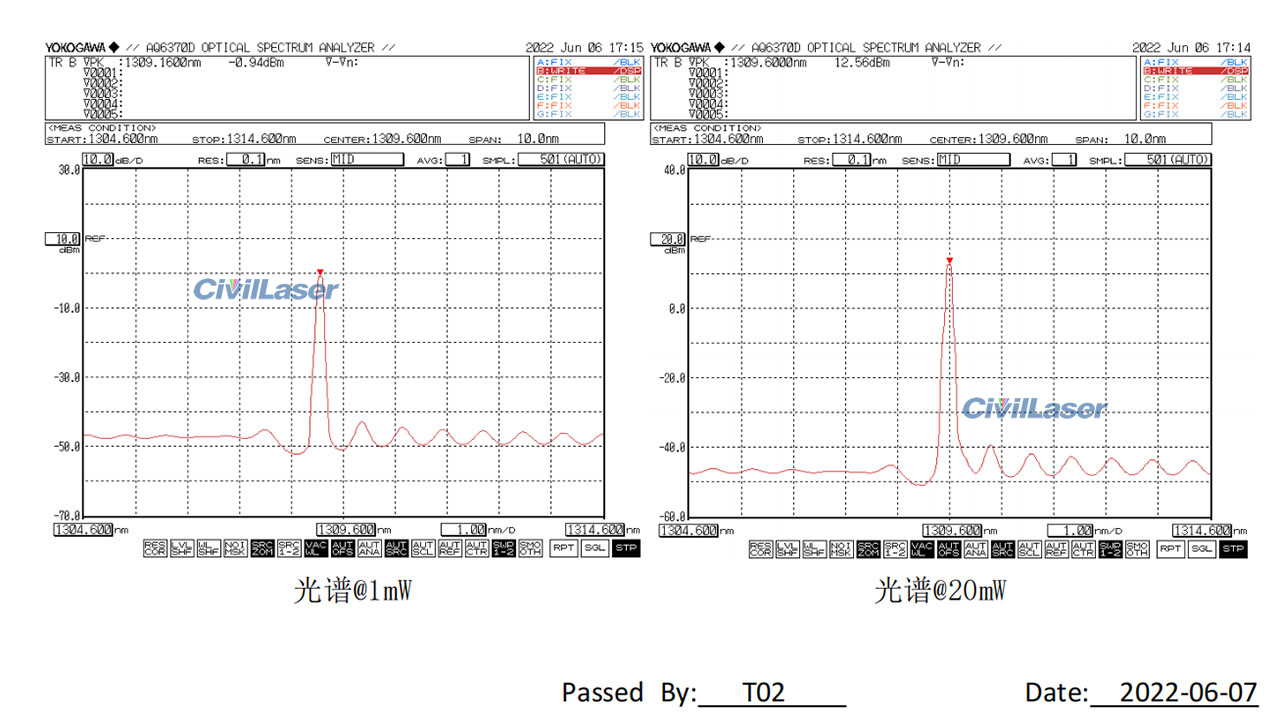

The test data for a 1310nm laser.

The spectra of the 1310nm laser at 1mW and 20mW respectively.

The test data for a 1310nm laser.

The spectra of the 1310nm laser at 1mW and 20mW respectively.

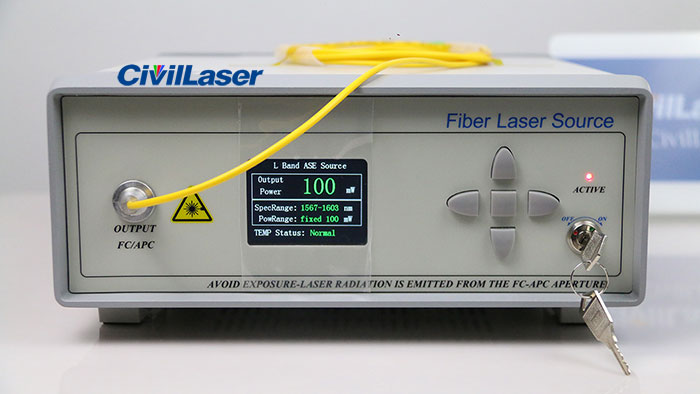

ASE Broadband Light Source with Two Fiber Outputs

This is a custom ASE broadband light source with built-in circulator. Unlike the standard ASE, this custom ASE has 2 fiber outputs. The two output fibers are the 2nd and 3rd fibers of the circulator. Let’s check it now.

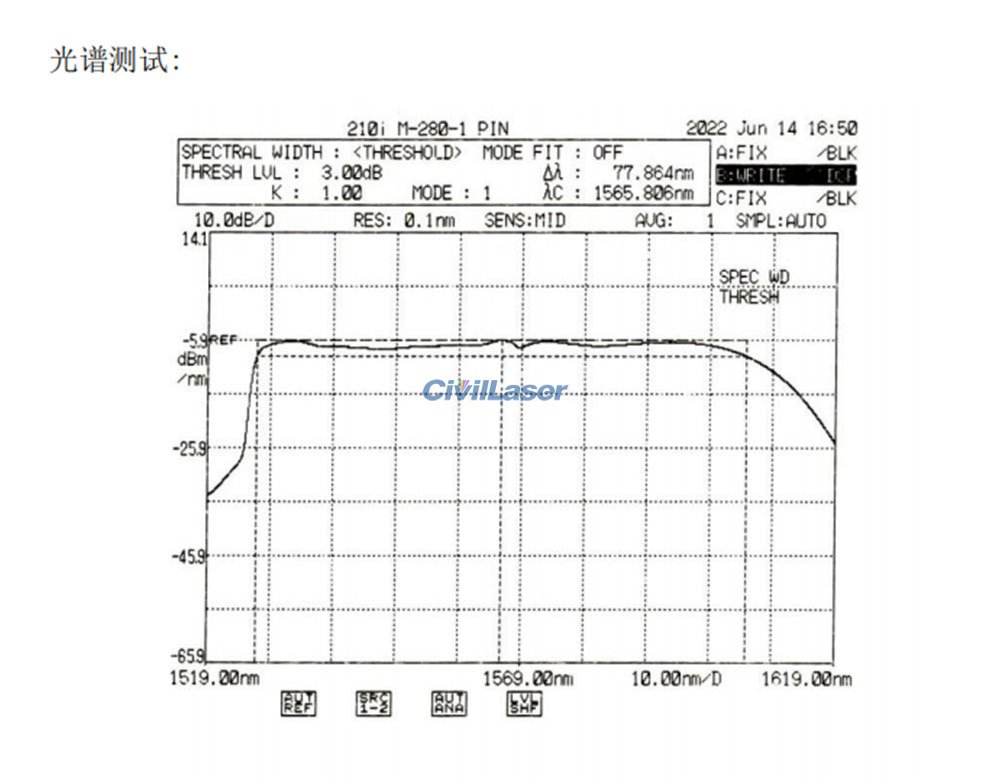

The fiber ASE broadband light source is an incoherent light source, which is the spontaneous radiation generated by the semiconductor laser pumping erbium-doped silica fiber, and the spectral flattening technology is introduced to achieve a broadband flat spectrum. The wavelength of the light source covers the C-band, and the spectral flatness is better than 2dB. It is output through single-mode fiber or polarization-maintaining fiber, which is suitable for applications such as fiber sensing.

CivilLaser can customize various ASE light sources according to customer needs. The wavelength range of C-Band, L-Band, C+L band is optional. Fibers are available in SM and PM. It can be customized whether to add a circulator. The output power can be customized as adjustable power. Software control function can be added. General models are listed on the web page, if you need special customization, please contact us.