Category Archives: CO2 Laser

1550nm 3kHz Linewidth PM Fiber Laser Source Benchtop

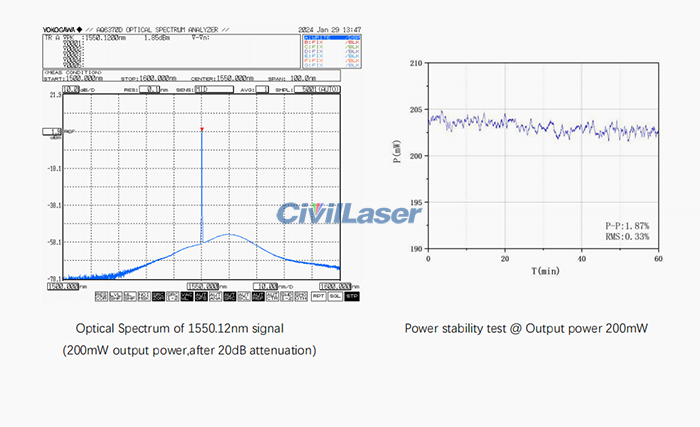

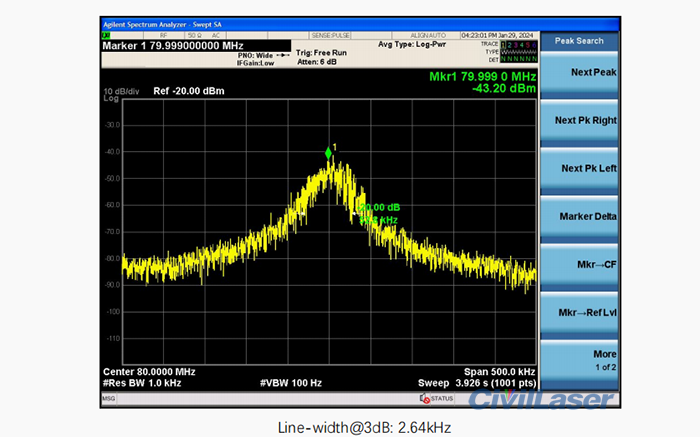

Single frequency narrow linewidth fiber laser adopts rare earth doped fiber DFB laser cavity structure, output single longitudinal mode laser with wavelength of 1550nm, spectral linewidth is less than 3kHz, output spectral side mode suppression ratio exceeds 60dB.

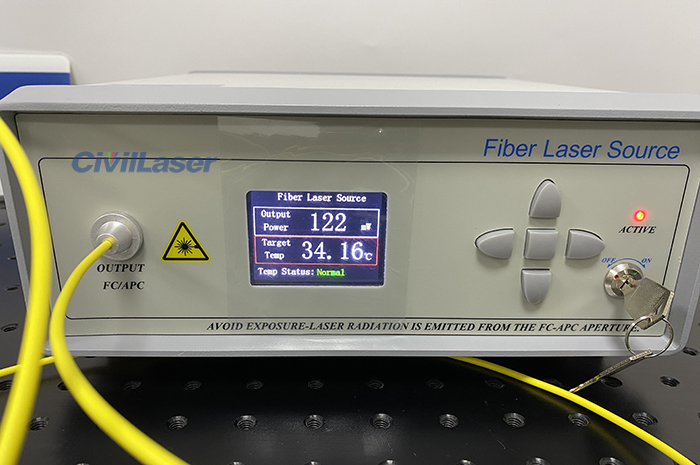

What we demonstrate in the video is a 1550nm 200mW narrow linewidth fiber laser with a linewidth of 2.64kHz. The output optical fiber is available in SM/PM, here is the PM optical fiber. And it is fixed on the laser and is not pluggable. The optical fiber interface and length can be customized.

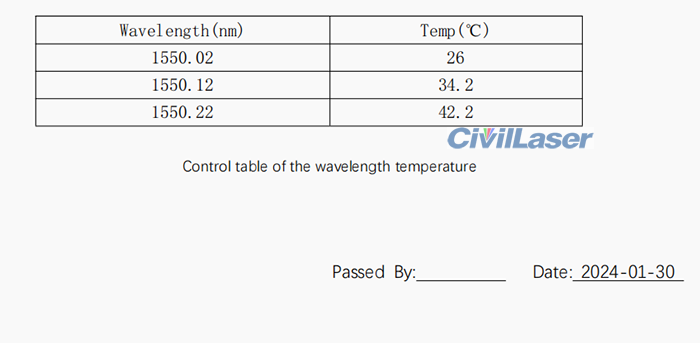

The laser output power can be adjusted through the button, the adjustment range is 10%~100%, and the adjustment accuracy is 1mW. The working Temperature can be fine-tuned, which can affect the laser wavelength. The adjustment accuracy is 0.01℃. The laser can also be controlled through software, and the interface on the laser is RS2023.

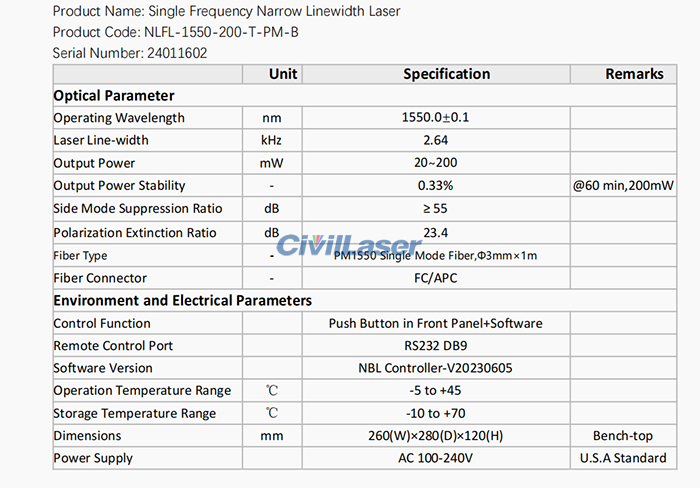

Parameter table of 1550nm narrow Linewidth Laser.

How to clean Laser lens , CO2 laser lens cleaning

How to clean Laser lens , CO2 laser lens cleaning

.jpg)

Step1:

Be flexible cleaning against light pollution (dust, fiber particles)

Use a blow balloon, blown off the contaminants which scattered on the surface of the optical element.

.jpg)

Step2:

Be flexible cleaning for slight contamination (stains, fingerprints)

Infiltration a unused swab or cotton balls with acetone or isopropyl alcohol] . Gently wipe the surface of the optical element with a wet cotton, do not force friction. Drag wet cotton on the surface, drag speed control. The stay behind of the wet cotton liquid can be evaporate immediately, so they will not leave marks.

Can only use plain paper body stick cotton swabs, and high-quality medical cotton. We recommend the use of reagent grade acetone or isopropyl alcohol.

.jpg)

Step3:

Be strong cleaning for heavily polluted (splatter) optics

Infiltration a unused swab or cotton balls with acetone or isopropyl alcohol] . Gently wipe the surface of the optical element with a wet cotton.Wipe dry the excess isopropyl alcohol with a clean cotton swab on the optical element.If you removed the thin film coating.the performance of the optical element will be completely destroyed. If the color of the optical element is changed, it means the thin film coating has been removed, you need to replace a new one if the lens coatings damaged.