Category Archives: All Posts

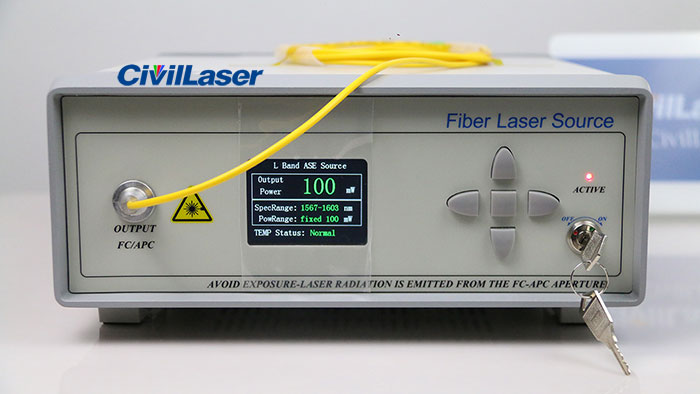

1310nm 20mW PM Fiber DFB Laser Source Benchtop

This is a 1310nm 20mW infrared laser coupled optical fiber. The fiber is PM1310 polarization-maintaining fiber, and SMF-28e single-mode fiber can also be customized. In addition, the single-mode fiber coupling interface is a consumable part, we make it into a fixed state and cannot be plugged or unplugged. The power of the laser output can be adjusted by the button, and the adjustment accuracy is 0.1mW. The back of the laser has an RS232 interface, and software control mode can be added.

1310nm single-wavelength laser light source uses DFB semiconductor laser chip, polarization-maintaining fiber output, professionally designed drive circuit and TEC control to ensure the safe and stable operation of the laser.

The test data for a 1310nm laser.

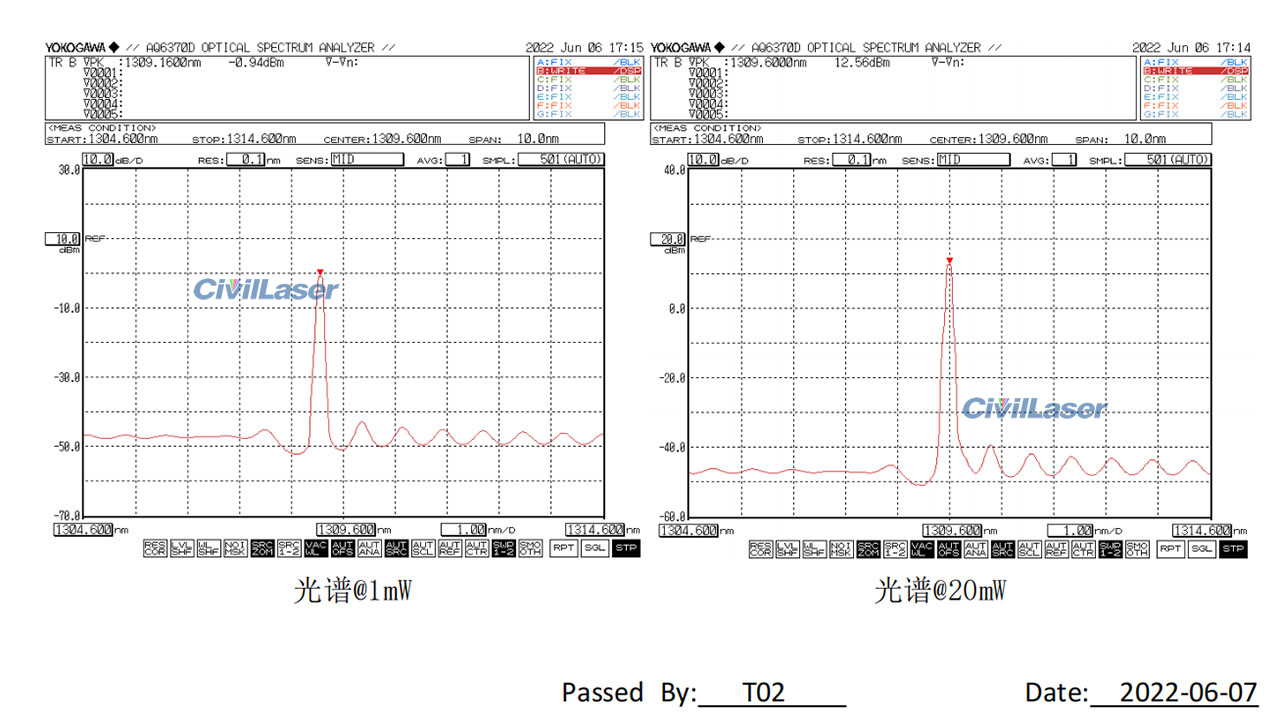

The spectra of the 1310nm laser at 1mW and 20mW respectively.

The test data for a 1310nm laser.

The spectra of the 1310nm laser at 1mW and 20mW respectively.

3IN1 DPSS Laser modulation CW/TTL/Analogue CivilLaser

3IN1 DPSS Laser modulation CW/TTL/Analogue

This video is from a 300mw Green DPSS Laser, the max out power is 300mw, and You can adjust the output power by adjusting the current.

it includes a Lab adjustable power supply. this kind of power supply support TTL and analogue signal input.

Analog Modulation VS TTL Modulation

Analog Modulation VS TTL Modulation

.png)

The default modulation is Analog. (TTL modulation can be customized. )

Analog modulation:

.jpg)

1. Use Analog modulation can adjust the laser output power.

2. We use 0~5V voltage as the analog single.

TTL modulation:

.jpg)

1. High voltage signal turn on the laser power, low voltage signal turn off the laser power.

2. The high voltage is about 3V, The low voltage is about 1V.

3500mw blue laser pointer button issue

1. First of all, please make sure the batteries work well and installed correctly.

Use 2 x 16340 or 2 x 18650 or 2 x 26650;

Positive to laser head;

Never use 3 batteries together;

.jpg)

.jpg)

.jpg)

.jpg)

2. Use a 5V USB wire test the laser head.

Remove the battery tube compartment, there is a interface can connect the 5v USB power.

3. Tight the end cap.

Back button issue/switch issue – Confirm other parts can work normally

Back button issue

Confirm other parts can work normally!

In this case, we only need to send a new Tail-hood button to our customer.

How to clean Laser lens , CO2 laser lens cleaning

How to clean Laser lens , CO2 laser lens cleaning

.jpg)

Step1:

Be flexible cleaning against light pollution (dust, fiber particles)

Use a blow balloon, blown off the contaminants which scattered on the surface of the optical element.

.jpg)

Step2:

Be flexible cleaning for slight contamination (stains, fingerprints)

Infiltration a unused swab or cotton balls with acetone or isopropyl alcohol] . Gently wipe the surface of the optical element with a wet cotton, do not force friction. Drag wet cotton on the surface, drag speed control. The stay behind of the wet cotton liquid can be evaporate immediately, so they will not leave marks.

Can only use plain paper body stick cotton swabs, and high-quality medical cotton. We recommend the use of reagent grade acetone or isopropyl alcohol.

.jpg)

Step3:

Be strong cleaning for heavily polluted (splatter) optics

Infiltration a unused swab or cotton balls with acetone or isopropyl alcohol] . Gently wipe the surface of the optical element with a wet cotton.Wipe dry the excess isopropyl alcohol with a clean cotton swab on the optical element.If you removed the thin film coating.the performance of the optical element will be completely destroyed. If the color of the optical element is changed, it means the thin film coating has been removed, you need to replace a new one if the lens coatings damaged.

Instruction: 980nm 3W 3000mw Infrared Laser Pointer invisible laser pointer

Product Link:

http://www.lucklaser.com/980nm-3w-3000mw-infrared-laser-pointer-invisible-laser-beam-p-172.html

1. Load Batteries: : Load “-” negative end of battery first.

2. Switch on the Tail Switch:: There are two options of tail

switches, one is the Keylock Switch, the other is the Simple Button

Switch.

2-1: The Keylock Switch: Turn into the keylock on tailcap with

the key Clockwise, the LED indicator will turn on.

2-2: Simple Button Switch: Depress the button on the tailcap, the

LED indicator for the power supply will turn on.

3: Turn the Beam On

3-1: Constantly On/Off Button: the lower button

▃ Depress Constantly On/Off Button,the beam is on.

▃ Depress it again,the beam is off.

3-2. Momentarily On/Off Button: the upper button

▃ Depress the Momentarily On/Off Button, the beam is on.

▃ Loosen the press, the beam is off.

4..Switch the Beam Off

▃ Press the Constantly on/off button to turn the beam off.

▃ Switch the beam off at any state by pressing the tail power

switch.

Comparison of brightness of light spot and beam among lasers of different wavelengths

Comparison of brightness of light spot and beam among lasers of different wavelengths

Some beginners often ask me how much the power of 532nm laser equivalent to the brightness of 445nm laser is

The question may not be so easy to answer, because the sensitive degree of each eye to light of different wavelengths is not the same.

And the feelings will be also different in the dark and light conditions .

Scientists have established light / dark vision functions respectively according to the mean value of human vision in the light / dark environments.

When the brightness is more than 3cd/㎡, it is a photopic vision, and pyramidal cells play a major role, peak value of V(λ)will be between 550nm~560nm; when the brightness is less than 0.03cd/㎡, it is a scotopic vision, rod cells play a major role, peak value of V(λ)shifts to short wavelength, equivalent to blue green parts between 500~510nm. Functions with brightness between 3~0.03 also appear in this position.

First let’s discuss the spot brightness. Spot brightness is basically decided by visual function when the power and density are the same.

The function value of 532nm is very high both in light and dark conditions, so it has relatively high brightness.

While the function value of 445nm is quite different in light and dark conditions, theoretically, the brightness is very low in daytime and has a good effect in night.

But, in fact, we also need to consider the factor of the main light.

For example, observe spots in the sunlight.

This is the power distribution of sun light.

Spot brightness also depends on the difference value of light source.

Just like 445nm, it is in a depressed position of solar spectrum, so it has a obvious contrast that the brightness of observation under sunlight has improved.

Next, let’s talk about the beam brightness.

Beam brightness is not only related with vision function but also has a great relationship with the scattering rate.

Even when they have the same power and beam diameter, because the air scattering rate is not the same, their power density will be different.

Atmospheric scattering is divided into various types, some have a stronger scattering to short wave, while some have basically the same scattering to full waves.

So this has enhanced beam brightness of short wave like 445nm once again, but it has also increased the loss of distant 445nm beam, therefore, 445nm beam often looks bright up close and dark at a distance.

Finally, I would like to remind of the safety of yourselves and others.

Ensure that there is no any personnel near light path or new light path that may be generated by reflection.

We are not recommending to observe laser spot up close with naked eyes without any protection.

Bonding crystal, optical cement crystal, separated crystal

Bonding crystal, optical cement crystal, separated crystal

First introduce the principle of 532nm laser

808nm semiconductor laser diode (LD) of pumping source supplies energy to laser crystal

Most of crystals are Nd:YVO4, some are Nd:YAG, both have Nd3+ ions and can produce 1064nm infrared laser

Infrared laser turns into 532nm green light through KTP nonlinear frequency doubling crystal

So, 532nm has 2 crystals, including laser crystals and frequency doubling crystal, the combination method of these two crystals include bonding, optical cement and separation.

Bonding crystal. UV light adhesives are adopted to bond crystals. If the power is relatively large, the crystals will be heated up quickly, then that would be a tragic if adhesives may come unglued after expansion and contraction. The extreme power of agglutination crystal is 200mw and its stability is poor

Optical cement crystal. A special treatment is conducted to contact surface of crystals (estimated to be highly polished), then crystals will be pressed together, crystals after this treatment will not be easy to come unglued as molecular forces integrate and their stability are relatively high, good for lasers below 300mW

Separated crystal. 2 crystals are separately placed for independent cooling, it can withstand a great power. Its weaknesses is that complex adjustment is needed to change the crystal position to achieve the maximum output and it has complex structure, large volume and high cost.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)